Effusion Cells

Scienta Omicron offers a wide range of highly reliable effusion cells. A broad range of Knudsen-type effusion cells, thermal crackers, and dedicated sources enable the evaporation of virtually any elemental or compound material.

Find the component for your application below and contact us for detailed information.

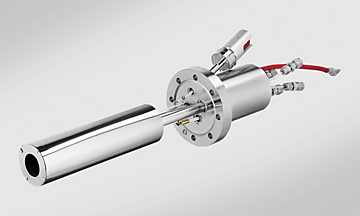

LTEC

The low temperature effusion cells are dedicated to the evaporation of high vapour pressure materials and of organic materials.

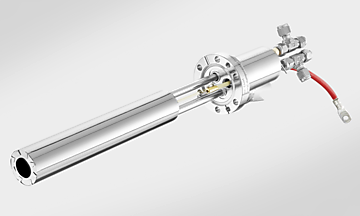

MTEC

The standard effusion cells are commonly used for sample preparation, thin film growth and for MBE applications. They are intended for the evaporation of elemental materials and compound evaporation or sublimation in the temperature range up to 1400 °C.

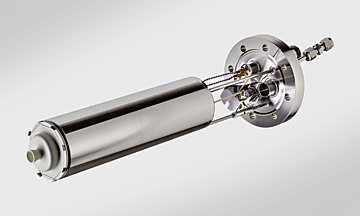

HTEZ/HTS

The high temperature effusion cells are designed for low vapour pressure elements and compounds evaporated or sublimated at temperatures up to 2000 °C.

PEZ

The Production Effusion Cells (PEZ) are supplied with conical or cylindrical crucibles and offer very precise flux reproducibility and excellent thickness uniformity. By using a customised beam shaping PBN insert in combination with a large capacity crucible further improvements of source material utilisation and flux stability are achievable.

OREZ

The Oxygen Resistant Effusion Cell (OREZ) is designed for the operation in oxygen rich or reactive gas atmosphere for a pressure range from 10-4 mbar/torr up to several mbar/torr.

OME

The Organic Molecules Effusion (OME) Cells show excellent low temperature properties. Due to the thermal conduction cooling concept the OME cell is ideally suited for the evaporation of temperature sensitive materials like organic molecules (OLEDs) or polymers.

SUSI

The Silicon Sublimation Source SUSI was developed for growing thin Si layers, short period Si/Ge superlattices and Si/SiGe heterostructures. It allows for growth of thin epitaxial Si layers with a crystal quality not otherwise possible by evaporation from effusion cell crucibles.

SUKO

The Carbon Doping Source SUKO is a highly optimised source for carbon p-type doping in III-V MBE. The SUKO provides a very clean and constant flux at a low deposition rate up to 2 Å/min. A maximum total layer thickness of 5 µm C with one filament is reported, by what layers of up to 1 mm highly carbon-doped GaAs are achievable.

DECO

The Phosphorus Doping Source DECO is an ultra-pure source for P2, based on the decomposition of GaP. At typical operation temperatures of about 600 °C - 700 °C, GaP is essentially decomposed into Ga and P2. Additional cracking is not necessary and the accumulation of P4 (white phosphorus) is reduced to a minimum.

Hydrogen Cracker Source (HABS)

The Hydrogen Atom Beam Source (HABS) is a thermal gas cracker which produces an ion-free hydrogen gas beam to avoid ion induced damage of the substrate. In comparison to hydrogen sources based on electron bombardment heating the HABS is heated by a DC operated tungsten filament.

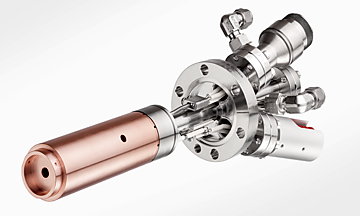

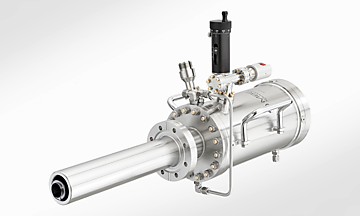

Valved Arsenic Cracker Source (VACS)

The Valved Arsenic Cracker Source (VACS) has been designed for high performance growth of III-V materials. It is highly specialised for As4 or As2 sublimation and combines a large crucible capacity of 300 cm³ or 500 cm³ with precise and fast flux control. A flux control over a pressure range of more than two orders of magnitude is provided by the integrated valve mechanism.

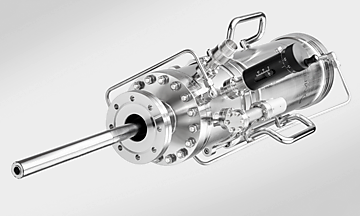

Valved GaP Compound Source (VGCS)

The Valved GaP Compound Source (VGCS) is a high purity P2-source, based on the decomposition of high purity GaP. The concept is derived from the DECO effusion cell. A mechanical valve mechanism has been added for rapid beam flux control.

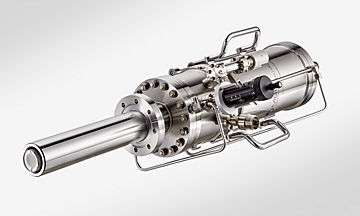

Valved Corrosive Cracker Source (VCCS)

The Valved Corrosive Cracker Source (VCCS) is designed for controlled injection of radicals of antimony, tellurium, magnesium or other corrosive materials in standard MBE applications. Parts directly exposed to the evaporant like the crucible, the valve mechanism, the injector tube and the cracker are solely made from PBN in order to minimise corrosion of the cell.

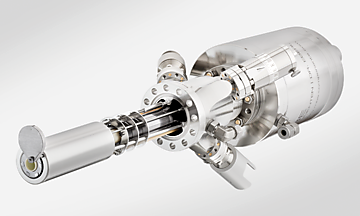

Thermal Cracker Cell (TCC)

The Thermal Cracker Cell (TCC) is an effusion cell equipped with a cracker stage with integrated water cooling shroud on its space-saving DN40CF (O.D. 2.75") flange. The cell features a crucible size of 35 cm3 or 130 cm3 which is sufficient for most R&D applications.