Materials Platform - Equipment and Instrumentation

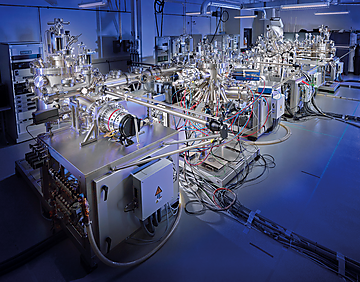

Scienta Omicron has a long history of providing customised solutions for the surface science field. Tailored instruments and large scale Materials Innovation Platforms (MIPs) offering unique capabilities is the best choice for the scientist breaking barriers in surface science techniques with extraordinary requirements.

Materials Innovation Platforms (MIPs) integrate instrumentation for growth with sophisticated in-situ characterization tools. Samples can thus be analysed at intermediate process steps to understand cause-effect correlations of a novel material’s growth and structure without leaving the clean UHV environment at any time. Scienta Omicron’s broad portfolio enables us to act as a single source supplier and a reliable partner for the design, production and in-field support, ensuring a smooth delivery process and a high system uptime.

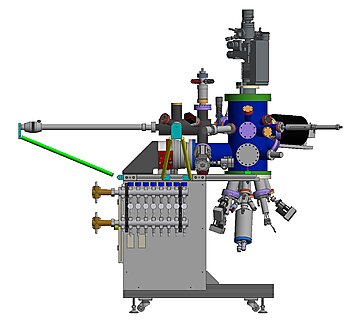

Materials Innovation Platform (MIP)

Scienta Omicron´s strength is to customise a wide range of methods and systems in one instrument – the multi-technique philosophy -- Materials Innovation Platforms (MIPs). We tailor standard cost-effective systems to your needs or design dedicated tools e.g. by combining Thin Film growths with high performance XPS ultimate resolution to solve your scientific questions.

CREATE Platform

CREATE combines the modules of a proven design solution to form an advanced UHV research system solution with guaranteed specifications. Designing a system using the CREATE platform with your Scienta Omicron expert provides clear decision pathways for capabilities and specifications.

Have a look for exciting customer solutions !

Based on history of more than 1000 UHV systems, we have selected a few exciting examples tailoring solutions to the experimental needs of our customers. With our reference finder, customised solutions can be filtered via the more than 85 different surface analysis and deposition techniques we offer.

Technical Backbones

Materials Innovation Platforms (MIPs) integrate instrumentation for growth with sophisticated in-situ characterization tools. Samples can thus be analysed at intermediate process steps to understand cause-effect correlations of a novel material’s growth and structure without leaving the clean UHV environment at any time. Scienta Omicron’s broad portfolio enables us to act as a single source supplier and a reliable partner for the design, production and in-field support, ensuring a smooth delivery process and a high system uptime.

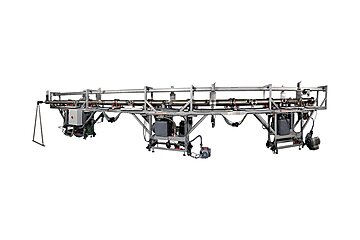

Linear Transfer Line (LTL)

The Linear Transfer Line (LTL) is a backbone for reliable and convenient sample handling in large UHV systems. Its modular design allows for cost-effective individual configurations, particularly of its length, the pumping system and the sample plates or wafers used. The LTL is easy to extend with additional segments to allow users to extend their UHV cluster step-by-step.

Radial Distribution Chamber (RDC)

The Radial Distribution Chamber (RDC) is based on a continuously rotatable telescopic transfer arm that can be equipped with a variety of end effectors for flag-style sample holders or wafer carrier rings for up to 4” wafers. The port configuration of the RDC can be adjusted to arrange the connected modules such that the available lab space is used in an optimal way.

MISTRAL

The MISTRAL control system offers intuitive, user-friendly operation and full visualisation of all vacuum system components. MISTRAL is built on reliable industry technology and allows a complete and fast status overview and control of valves, pumps, pressure gauges and bakeout equipment. It is delivered with a preconfigured bakeout procedure, which can easily be adapted by the user. Several interlocks ensure a safe operation of the vacuum system at all times.

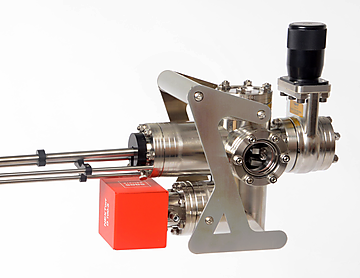

UHV Suitcase

The UHV suitcase offers a safe and convenient way to exchange up to six flag-style sample holders between separated UHV systems, be it in the same building or across continents. With its very compact shape and low weight, the suitcase can be mounted on a large number of UHV systems. True UHV conditions ensure that the samples arrive at their destination in perfect conditions.