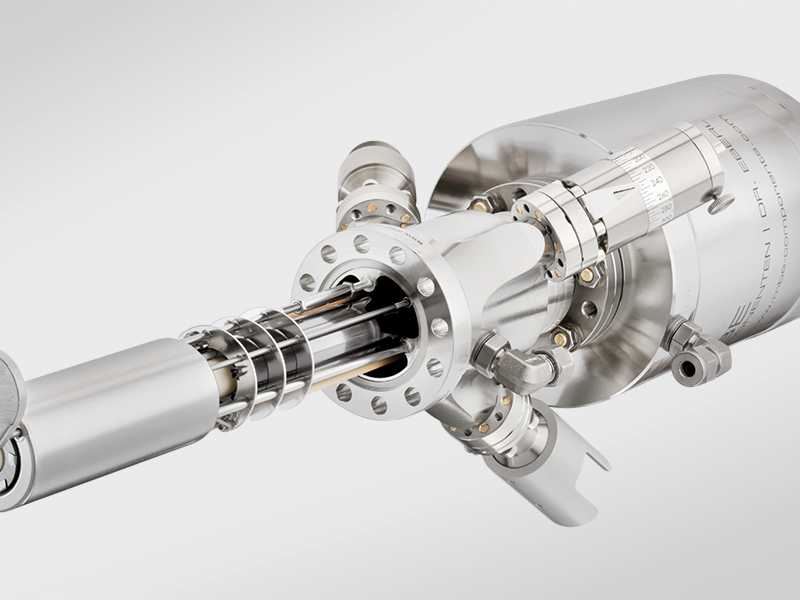

Thermal Cracker Cell (TCC)

Compact Cracker

- Full PBN solution for corrosive materials like Te, Sb, Se, As, Mg

- DN40CF (O.D. 2.75" ) mounting flange compatible with all MBE systems

- Thermal cracking up to 1300 °C

- 35 cm3 or 130 cm3 PBN reservoir

- Excellent thermal isolation between low temperature reservoir and hot cracking zone

- Integrated water cooling for cracker stage

- Integrated rotary shutter

The Thermal Cracker Cell (TCC) is an effusion cell equipped with a cracker stage with integrated water cooling shroud on its space-saving DN40CF (O.D. 2.75") flange. The cell features a crucible size of 35 cm3 or 130 cm3 which is sufficient for most R&D applications.

The TCC is designed for evaporation of materials at operation temperatures from 100 °C to 650 °C with an additional cracker stage on the end of the injector tube that provides temperatures up to 1300 °C. The crucible is heated by a tantalum wire heater. The standard crucible material suitable for most evaporants is PBN. The shielding of the crucible is reduced to optimize the cell for low temperature operation. That way a good flux control for high vapour pressure materials is possible without using an additional valve. The crucible and cracker zones are shrouded by water cooling, therefore, the thermal load on the chamber is neglectable. A source concept like this is used for high vapour pressure materials, which form atom clusters. Typical evaporation elements are As, Se, Sb, Te, Mg.