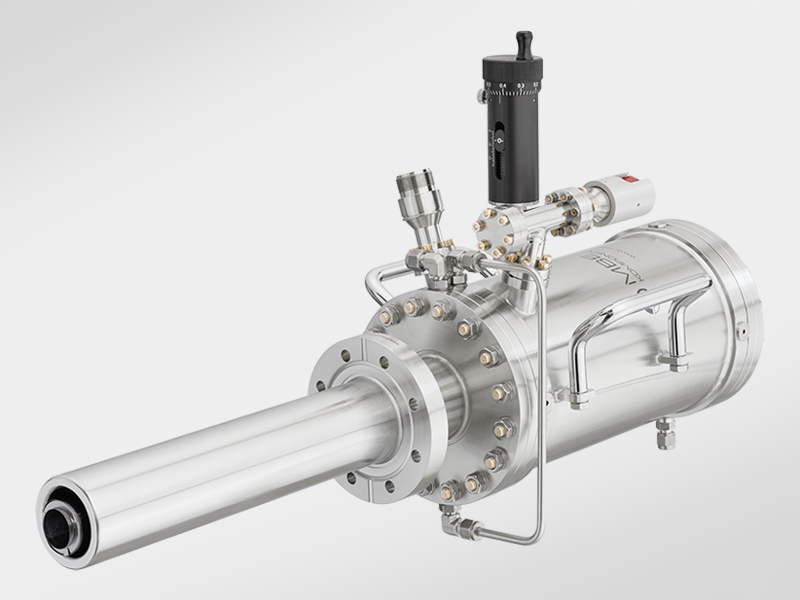

The Valved Arsenic Cracker Source (VACS) has been designed for high performance growth of III-V materials. It is highly specialised for As4 or As2 sublimation and combines a large crucible capacity of 300 cm³ or 500 cm³ with precise and fast flux control. A flux control over a pressure range of more than two orders of magnitude is provided by the integrated valve mechanism. The typical on/off ratio is about four orders of magnitude in pressure reading.

Due to the large valve opening it allows efficient pumping of the Arsenic reservoir in the open valve position. The valve unit can be operated manually or with a valve control unit. The integrated water cooling shroud and the use of selected materials for cell and valve unit guarantee high purity operation conditions. The operation mode of the source can be easily changed from As4 to As2 growth by the operation conditions of the integrated cracker unit.

Further Details:

- DN100CF (6” OD) mounting flange

- In-vacuum Diameter: 57 mm

- Crucibles 300 cm³ or 500 cm³

- Heating system with two separate heater-circuits for the cell and the cracker

- Two thermocouples Type C for the cell and the cracker

- Operating temperature of the cell crucible: 300-400 °C

- Operating temperature of the cracker: 450 °C (As4-mode) or 1100 °C (As2-mode)

- Outgassing temperature of the cell crucible: 500 °C

- Outgassing temperature of the cracker: 1200 °C

- Integrated water cooling shroud

- Bakeout temperature up to 300 °C

- Flux control with integrated valve unit

- Valve control either via hand control or by a motor drive with a control unit