Scanning Probe Microscopy Instruments

In 1987 - only one year after the Nobel Prize was awarded to Gerd Binnig and Heinrich Rohrer - our legendary STM 1 was created. Since those early times of STM we have continuously advanced our SPM product in order to support technology leaders and fore-front SPM researchers as well as application and material science focused SPM groups around the globe with state-of-the-art instrumentation.

Our modern scanning probe microscopes offer e.g. ultimate mechanical stability, ultra-long hold times at liquid Helium temperatures, options for strong magnetic fields in a flexible and customisable UHV system environment. We have carefully optimised our instruments to ensure outstanding signal qualities for QPlus® and STM operation to ensure excellent results in all relevant scanning and spectroscopy modes. In addition, we have also advanced controller technology enabling e.g. a new QPlus® operation mode called QSPEED simplifying QPlus® operation.

Most advanced techniques allowing for new experiments such as tip enhanced Raman, scanning tunneling luminescence, time resolved STM and electron spin resonance experiments enabled through adequate optical solutions or high frequency wiring.

In addition most advanced dry-technology allowing for convenient low temperature SPM operation without the need for cryogen liquids.

Find the component for your application below and contact us for detailed information.

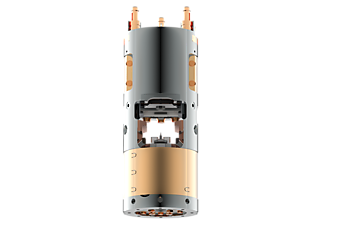

TRIBUS SPM

The ultra-compact TRIBUS is a universal SPM for a wide variety of applications. Whether for SPM-spectroscopy, surface imaging, or manipulation of nanoparticles, for experiments at elevated temperatures or at the milli-Kelvin scale, in high magnetic fields or in spatially tight environments, the TRIBUS SPM is the ideal choice whenever highest resolution, accuracy and flexibility are required.

MATRIX SPM Controller

The MATRIX 4 Control System builds on 30 years of experience in SPM technology and unlocks the full capacity of our leading-edge Scanning Probe Microscopes. The key features include intuitive and flexible experiment control; best-in-class noise floor; full 64-bit software; and modular upgrade paths.

SXM Controller

The new digital SXM Control System incorporates advances in state-of-the-art electronics and latest software algorithms to fulfill the needs of today’s and future challenges in scanning probe microscopy. Features of the new SXM Controller include low noise, large detection bandwidth, high resolution 24 bit D/A and A/D converters, easy software and hardware handling, accessible and simple file format and a basic data analysis software package.

CHC Controller

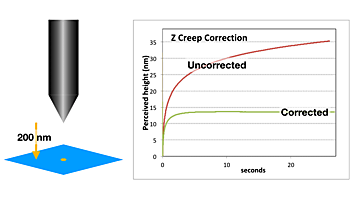

The ZyVector STM control system from Zyvex Labs uses live position correction to enable atomic-precision STM lithography. Now the same live position correction technology is brought to STM microscopy and spectroscopy users, enabling fast settling times after large movements in xy and z, and precise motion across the surface, landing and remaining at the desired location.

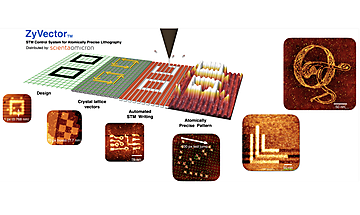

ZyVector

ZyVector is an STM control system which converts a scanning tunneling microscope into an automated STM lithography system. The system is controlled through our software package, Scanz, which allows for automation of almost every task, including Digital Vector Lithography. The software drives a 20-bit digital control box to handle the real-time control tasks such as the STM feedback loop and the creep and hysteresis correction which allows for precise tip positioning. This in drives high-voltage amplifiers to drive the STM piezo scanner. ZyVector is designed to connect to Scienta Omicron UHV STMs using the standard Scienta Omicron STM cabling. It can also be adapted to run other STM systems.

Tip Preparation Tool

The flange mounted tip preparation tool is designed for efficient cleaning of SPM tunneling tips. Especially etching remains or oxides can create artefacts or unstable tips during imaging or spectroscopy applications. The tip preparation tool offers heating up to temperatures above 1000°C at the tip to remove those remains.

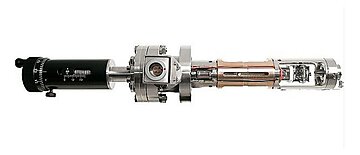

Tip Etching Tool

Accurate tip etching is achieved by the W-Tek semiautomatic etching device for the production of tungsten tips with an extremely small apex radius by etching in solution or by the lamella process. The etched tips are suitable for use in STM, FIM, FEM and SEM applications. The electronic control unit offers user-friendly facilities for monitoring of the etching voltage or current to provide optimum sensitive control of the etching process.