MISTRAL

Comfortable, Easy and Safe UHV System Operation

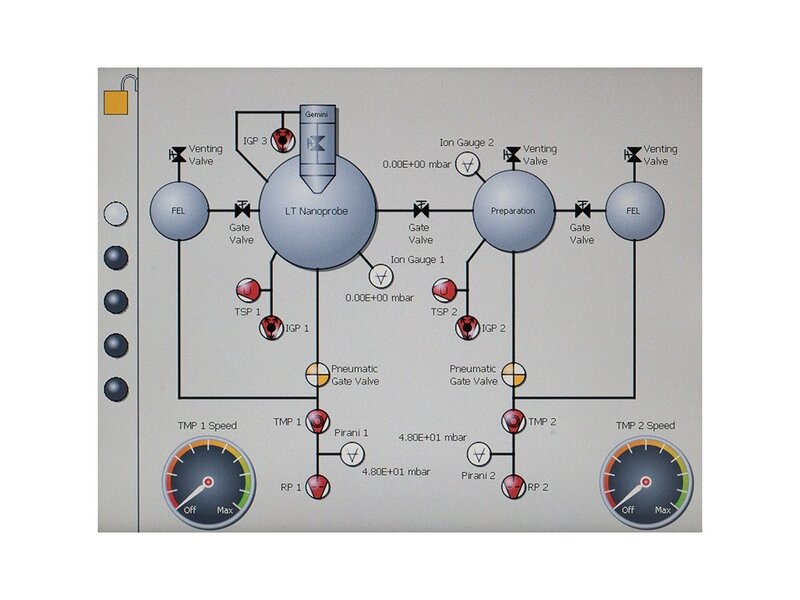

- Full visualisation of all vacuum system components at a glance

- Integrated interlocks and safety management

- Easily programmable bake-out with temperature history graph

- Highly individualised system

The MISTRAL control system offers intuitive, user-friendly operation and full visualization of all vacuum system components. MISTRAL is built on reliable industry technology and allows a complete and fast status overview and control of valves, pumps, pressure gauges and bakeout equipment. It is delivered with a preconfigured bakeout procedure, which can easily be adapted by the user. Several interlocks ensure a safe operation of the vacuum system at all times.

MISTRAL’s modular concept covers a wide range of vacuum components like pumps, pressure gauges, valves, stepper motors, temperature sensors, etc. It also ensures that the control system can be adapted to meet future upgrades of the vacuum system.

Besides the vacuum schematic, the user can chose to display other information relevant to the UHV system, such as the pressure readings in the vacuum chambers, bakeout progress, or control parameters for sample heaters or thin film devices, such as Knudsen cells.

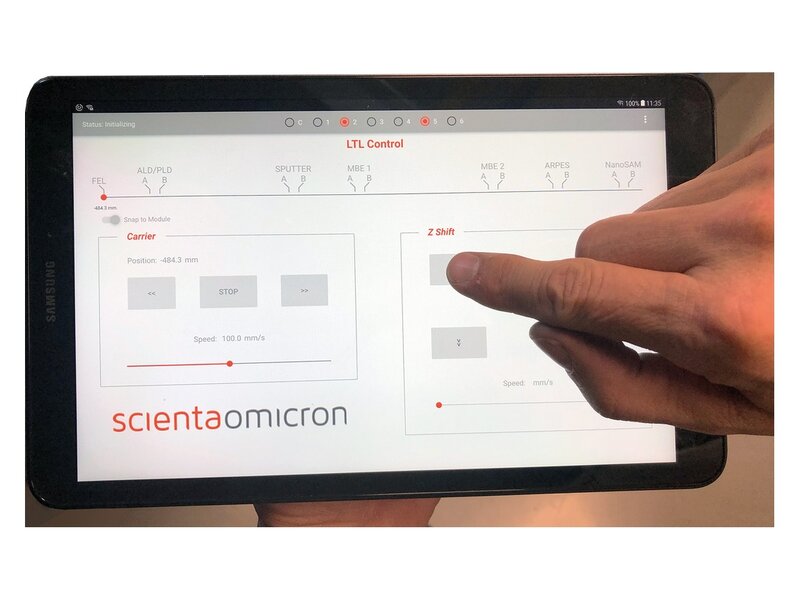

MISTRAL is employed to control motorised sample manipulators, Radial Distribution Chambers or Linear Transfer Lines without the need for any extra hardware. Our “Forbidden Spaces” are used as a special safety measure to prevent mechanical collisions between motorised items with and other hardware.

If necessary, specialists from Scienta Omicron’s headquarters can be given secure network access to support system upgrades, but also for remote diagnosis and service.