UHV Suitcase

Safe, Convenient and Versatile Sample Transfer

- Compact and lightweight (9.2 kg)

- True UHV conditions (< 1x10-10 mbar)

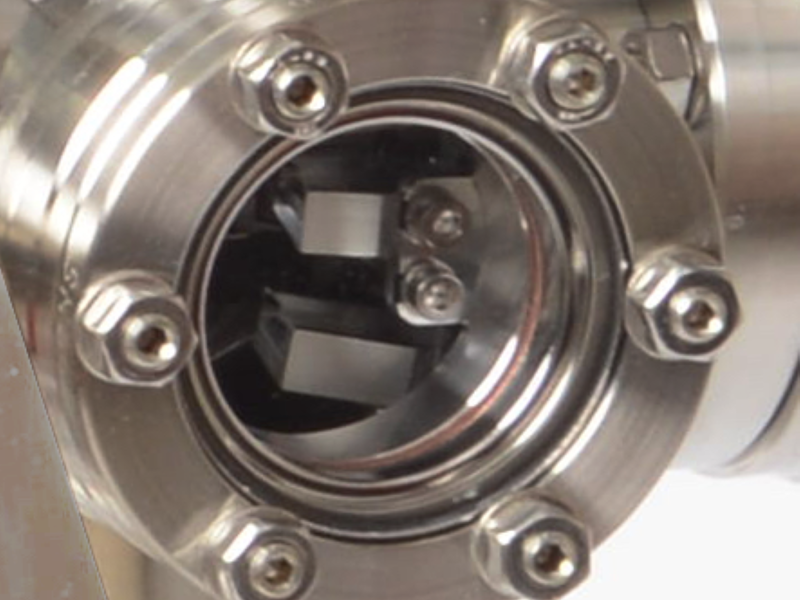

- Six secure storage positions for sample flags

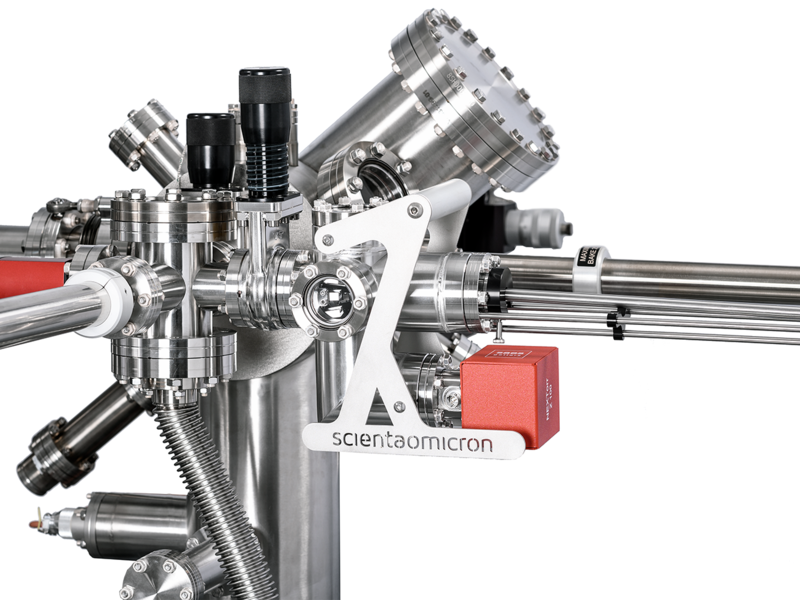

The UHV Suitcase offers a safe and convenient way to exchange up to six flag-style sample holders between separated UHV systems, be it in the same building or across continents. With its very compact shape and low weight, the suitcase can be mounted on a large number of UHV systems. True UHV conditions ensure that the samples arrive at their destination in perfect conditions.

The ever-increasing complexity of sample preparation and analysis requires collaborations between research groups, including sharing equipment such as synchrotrons or nano-structuring tools or even using a specialist‘s MBE capabilities. Sometimes sample exchange between incompatible systems within the same building also requires a UHV transport container, e.g. to avoid the connection of vibration-sensitive analysis equipment to production MBE systems with cryo-pumps.

Such a UHV transport container must fulfill the following requirements:

- Keep samples safe from external influence, minimise degradation by optimal UHV conditions, prevent samples from being touched or dropped

- Have a convenient and flexible design that is compact and light-weight, require little space on host systems, provide for a flexible sample transfer concept, and ensure short duration from mounting to sample transfer (i.e. pump-down and bakeout of intermediate transport-tubing)

- Allow for easy and inexpensive transport by plane, car, foot, in person or by a freight forwarder.

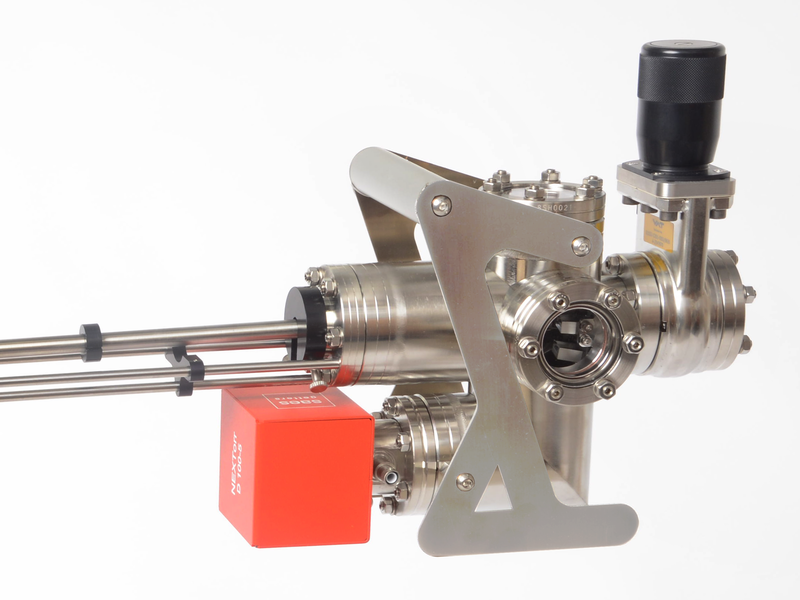

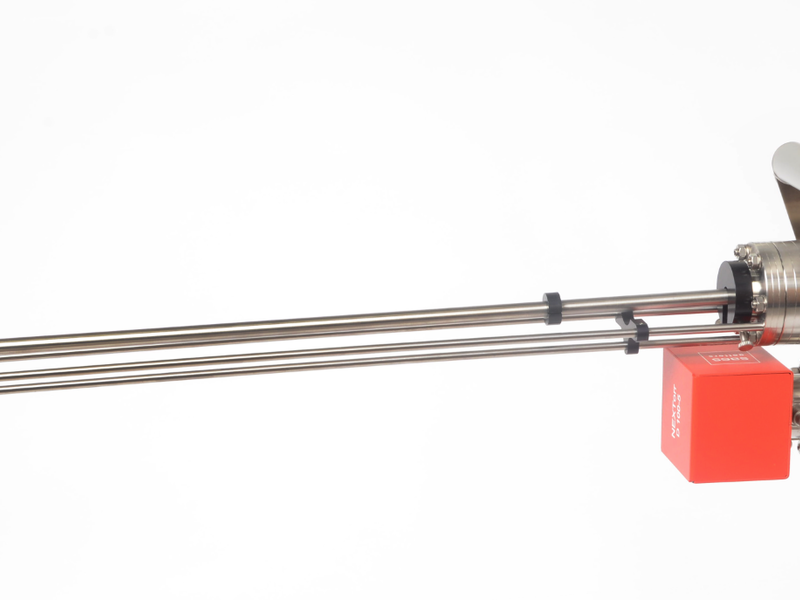

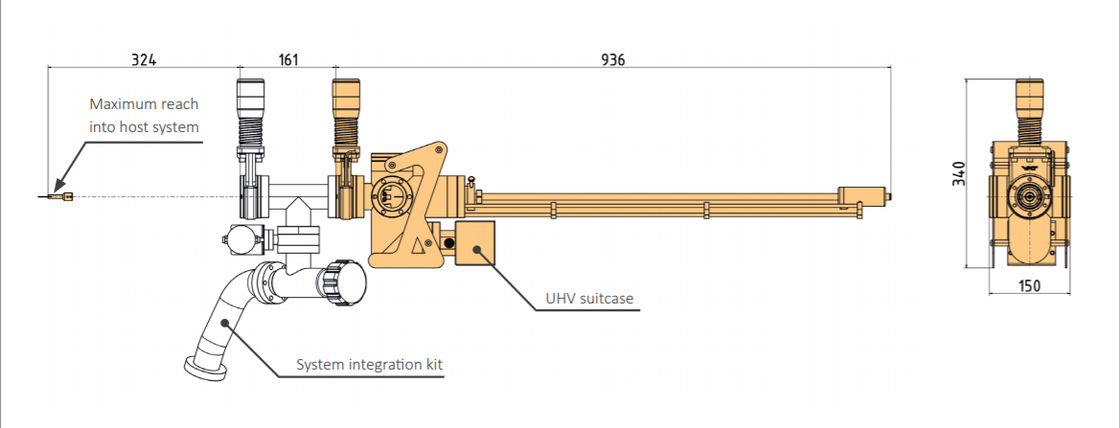

Scienta Omicron’s UHV suitcase meets these demands with a base pressure in the 10-11 mbar range and storage space for up to six flag-style sample holders, securely held in place by spring-loaded acceptor stages. With its combined ion/non-evaporable getter (NEG) pump, the suitcase has a weight of only 9.2 kg and a size of of only 940 mm (L) x 150 mm (W) x 340 mm (H).

The pump’s NEG element will continue to pump the suitcase even without external power, including during transport. The offering is completed with an optional system integration kit and tailor-made flightcase, which provides a robust outer packaging when samples are shipped without the personal attention of the scientist.

More Information

Easy Handling and System Integration

Due to its small size and low weight, it is easy for a single user to unmount the UHV suitcase from one host system, carry it to the next system by hand, and then mount it without any additional tools or the help of a second person.

Unless the suitcase is mounted onto a loadlock chamber, the system integration requires a DN40CF tee with a pumping line to a turbo pump to evacuate the volume between suitcase and UHV chamber. A system integration kit with all necessary vacuum components (tee, valves, pumping line, etc., but no pump and pressure gauge) is available as an option.

Its compactness reduces the risk of collisions with other components and allows the use of the vacuum suitcase on many UHV systems, including self-built, 3rd party and old Scienta Omicron systems.

Specifications

Factory acceptance: < 1x10-10 mbar

Site acceptance if part of a system: < 3x10-10 mbar

9.2 kg (without pump controller and flightcase)

Approximately 940 mm (L) x 150 mm (W) x 340 mm (H)

6 spring-secured positions for Scienta Omicron’s flag-style sample holders (base plate size: 15x18 mm², max. height: 8 mm)

320 mm with standard suitcase and system integration kit

> 180 °C

24 V DC, 1.8 kg,

288 mm (L) x 110 mm (W) x 82 mm (H)

System integration kit, flightcase, bakeout cover with integrated heater element, power supply for NEG activation, support frame

For full specifications and more information about product options, please do not hesitate to contact your local sales representative.

Reference Systems

Downloads

UHV Suitcase: Safe, Convenient and Versatile Sample Transfer

The ever-increasing complexity of sample preparation and analysis requires collaborations between research groups, including sharing equipment such as synchrotrons or nano-structuring tools or even using a specialist‘s MBE capabilities. Sometimes sample exchange between incompatible systems within the same building also requires a UHV transport container, for example, to avoid connection of vibration-sensitive analysis equipment to production MBE systems with cryo-pumps.