The PVD 50 System is designed to fulfil the highest and most stringent requirements of modern thin-film deposition. Real Ultra High Vacuum (UHV) base pressure reduces contaminations in the grown films and enables integration to surface science analysis instruments. The PVD 50 is suitable and optimised for the growth of metals, oxides, magnetic materials and superconductor material systems.

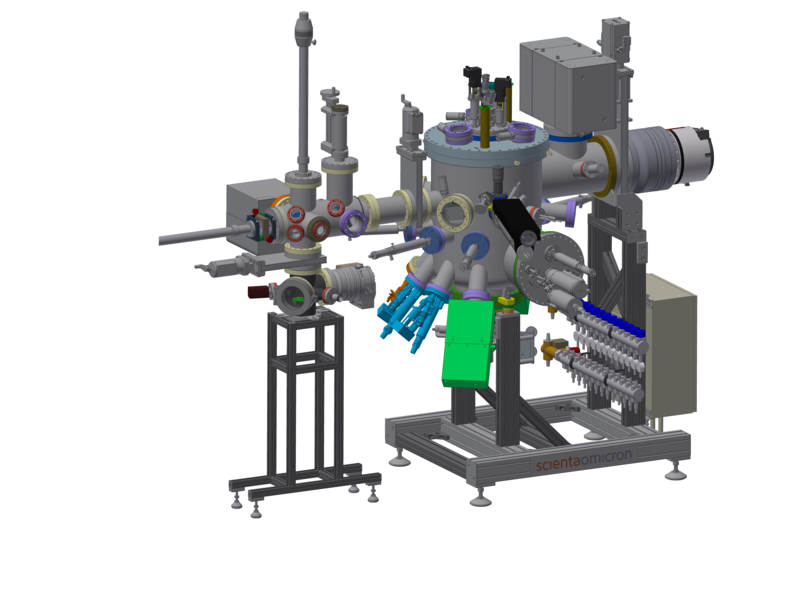

The PVD systems are dedicated growth systems with a load lock chamber and with an optional preparation/storage chamber. The substrate sizes are either 2” or alternatively, the systems can be adapted to surface science sample plates. The carefully designed chamber enables the usage of several electron evaporators and sputter sources at the same time, which is important for co-deposition.

Due to the small footprint the PVD 50 system can be configured to be either a standalone system with a buffer chamber and sample load lock or integrated with a linear transfer line or a radial distribution chamber as a part of a Materials Innovation Platform (MIP).

All PVD 50 systems come with the MISTRAL control system. The control system is based on certified standard components for supreme reliability and provides a graphical status overview of all sensor values.

Specifications

Target Specification*

Stainless steel

< 3×10-10 mbar

Ion gauge

Up to 2“ diameter

2x DN100CF Sputter sources

1x DN250CF Multi-Pocket electron beam evaporator

2x DN63CF Vertical e-beam evaporators

2x DN63CF Plasma sources

1. Ion getter pump (IGP) and Cryopump

2. Ion getter pump (IGP) and Turbopump

3. Others available on request

Equipped with Viewport Shutters

Equipped with Viewport Shutters

2x Quartz Micro Balance

Quadrupole mass analyser (RGA)

Pyrometer

* Specifications for standard configuration. Customizations can influence specifications. Please contact us for details.

Downloads

PVD 50 System Brochure

The PVD 50 system is designed to fulfill the highest and most stringent requirements of modern thin-film deposition. Real Ultra High Vacuum (UHV) base pressure reduces contamination in the grown films and enables integration to surface science analysis instruments. The PVD 50 is suitable and optimised for the growth of metals, oxides, magnetic materials and superconductor material systems.