BAR XPS

For Studies of Industrially Relevant Catalytic Reactions

PES HAXPES APPES APXPS AP-HAXPES XPS

- Study of catalytic reactions

- Measuring XPS under conditions of > 1 bar of pressure

- Open-up the possibility of operando studies of heterogeneous catalytic reactions under industrial manufacturing conditions

- Patented technology: SE 542 905 C2, SE 542 904 C2, SE 542 903 C2, SE 542 902 C2

It is estimated that up to 90% of chemical products are produced via catalysis. Many heterogeneous catalytic reactions occur at high pressures and temperatures. To study these types of catalytic reactions, researchers at Stockholm University have constructed an instrument based on Scienta Omicron’s electron spectrometer capable of measuring XPS under conditions of > 1 bar of pressure in the vicinity of the catalytically reactive surface. Through collaboration this capability is available through Scienta Omicron.

The performance of the instrument is demonstrated by measuring bulk 2p spectra from a copper single crystal at He pressures of up to 2.5 bar and C 1s spectra in gas mixtures of CO + H2 at pressures up to 790 mbar. The capability of the instrument opens up the possibility of operando studies of heterogeneous catalytic reactions under industrial manufacturing conditions.

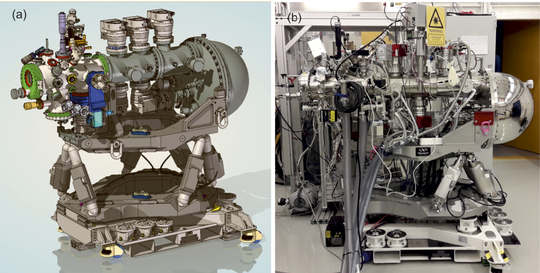

Peter Amann and Anders Nilsson, et. al. present the instrument, which consists of a HiPP-2 analyser, in the Review of Scientific instruments article ´A high-pressure X-ray photoelectron spectroscopy instrument for studies of industrially relevant catalytic reactions at pressures of several bar´.

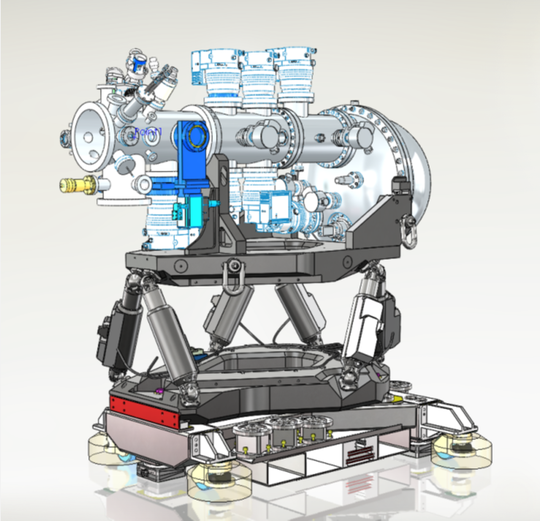

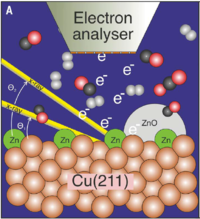

The instrument follows a modular design with 3 main components: 1) an electron analyser (Scienta Omicron, R4000 & HiPP-2), 2) a main chamber with movable high precision frame, and 3) a high precision hexapod for alignment.

More Information

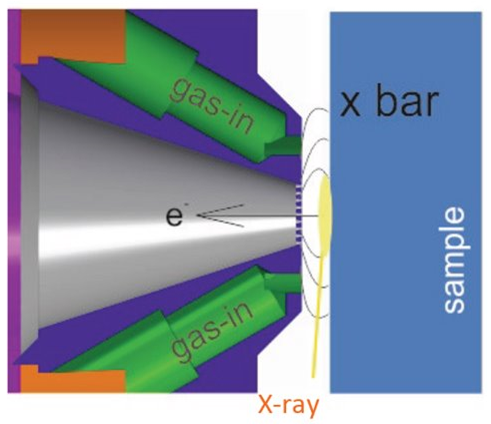

Virtual Gas Cell

Bar XPS uses the virtual gas cell design, which creates a high local pressure area around the sample of > 1 bar.

- The high pressure zone is localized around the sample

- The virtual gas cell lowers gas consumption

- The gas flow reduces the sample contamination

- The virtual cell removes risk of equipment damage due to over pressur

Research

A high-pressure x-ray photoelectron spectroscopy instrument for studies of industrially relevant catalytic reactions at pressures of several bars

Peter Amann, David Degerman, Ming-Tao Lee, John D. Alexander, Mikhail Shipilin, Hsin-Yi Wang, Filippo Cavalca, Matthew Weston, Jörgen Gladh, Mikael Blom, Mikael Björkhage, Patrik Löfgren, Christoph Schlueter, Patrick Loemker, Katrin Ederer, Wolfgang Drube, Heshmat Noei, Johann Zehetner, Henrik Wentzel, John Åhlund and Anders Nilsson

Review of Scientific Instruments 90, 103102 (2019); https://doi.org/10.1063/1.5109321

Results

In-situ probing of the Fischer-Tropsch reaction on Co single crystal surfaces up to 1 bar

The surface chemistry of the Fischer-Tropsch catalytic reaction over Co has still several unknows. Here, we report an in-situ X-ray photoelectron spectroscopy study of Co(0001) and Co(10-14), and in-situ high energy surface X-ray...

Operando Probing of the Surface Chemistry During the Haber–Bosch Process

The large-scale conversion of N2 and H2 into NH3 over Fe and Ru catalysts for fertilizer production occurs through the Haber-Bosch process, which has been labelled the most important scientific invention of the 20th century....

Operando Observation of Oxygenated Intermediates during CO Hydrogenation on Rh Single Crystals

The CO hydrogenation reaction over the Rh(111) and (211) surfaces has been investigated operando by X-ray photoelectron spectroscopy at a pressure of 150 mbar. Observations of the resting state of the catalyst give mechanistic insight...

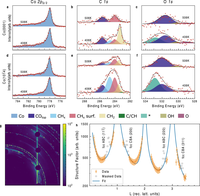

The State of Zinc in Methanol Synthesis over a Zn/ZnO/Cu(211) Model Catalyst

The active chemical state of zinc (Zn) in a zinc-copper (Zn-Cu) catalyst during carbon dioxide/carbon monoxide (CO2/CO) hydrogenation has been debated to be Zn oxide (ZnO) nanoparticles, metallic Zn, or a Zn-Cu surface alloy. We used...

Downloads

BAR XPS Brochure

Discover the new high-pressure XPS system from Scienta Omicron, developed at Stockholm University. Designed for operando studies of industrially relevant catalytic reactions, it enables XPS measurements at pressures above 1 bar, providing unique insights into chemical processes as they happen.