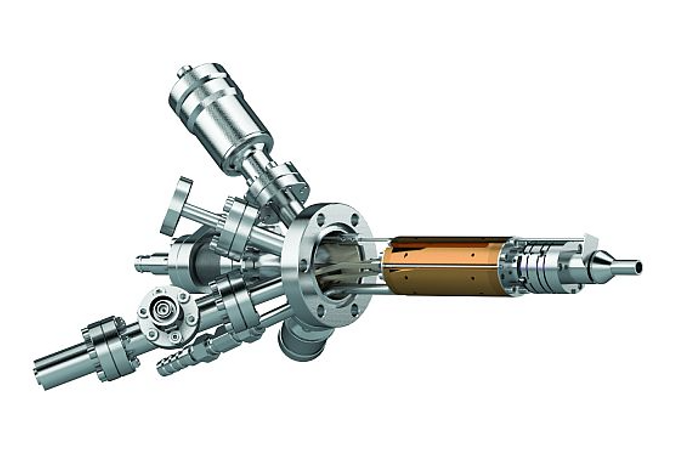

EFM 3i (IBAD)

Specifically Designed to Work with Ion-Beam-Assisted Deposition (IBAD)

- Ion focusing lens for Ion-Beam-Assisted Deposition (IBAD)

- Ion suppression

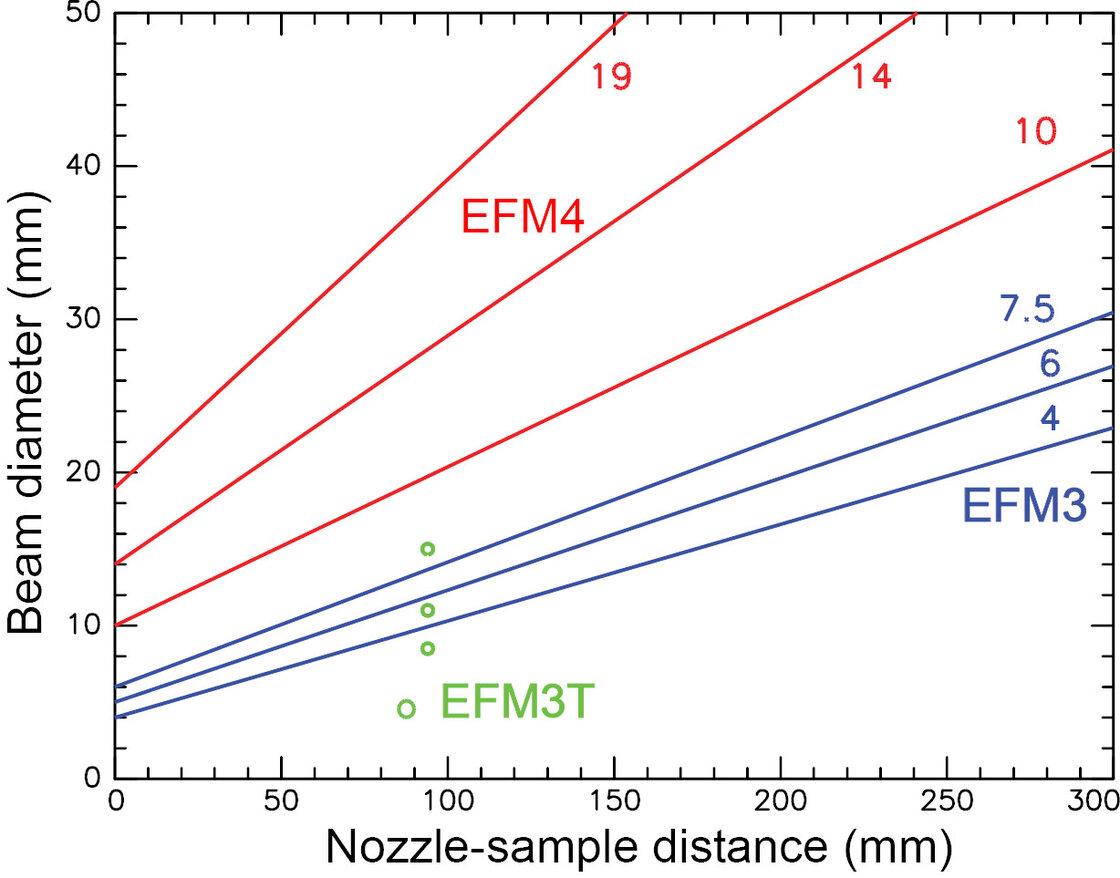

- Evaporation area Ø 4 - 20 mm

- Flux monitor and integrated shutter

- Rear-loading of evaporation material as rod or in crucible

- Ease-of-operation with Lab VIEW TM –based Epitass® software

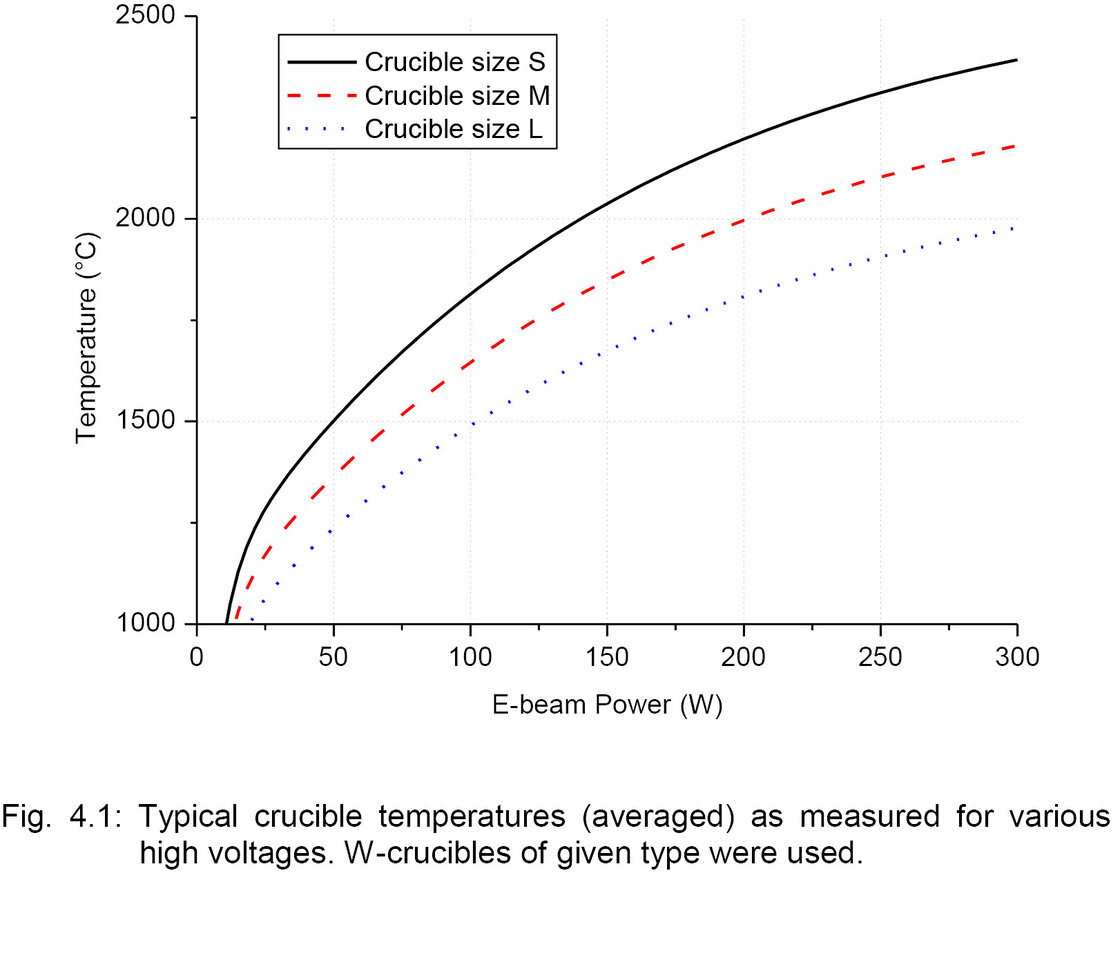

- Crucible temperature display

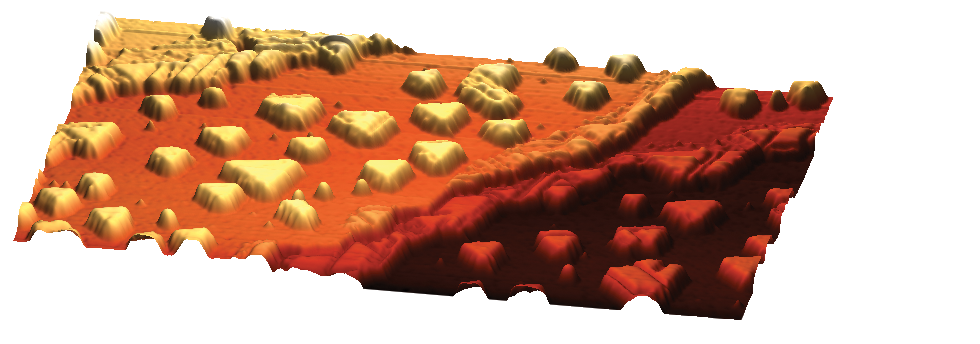

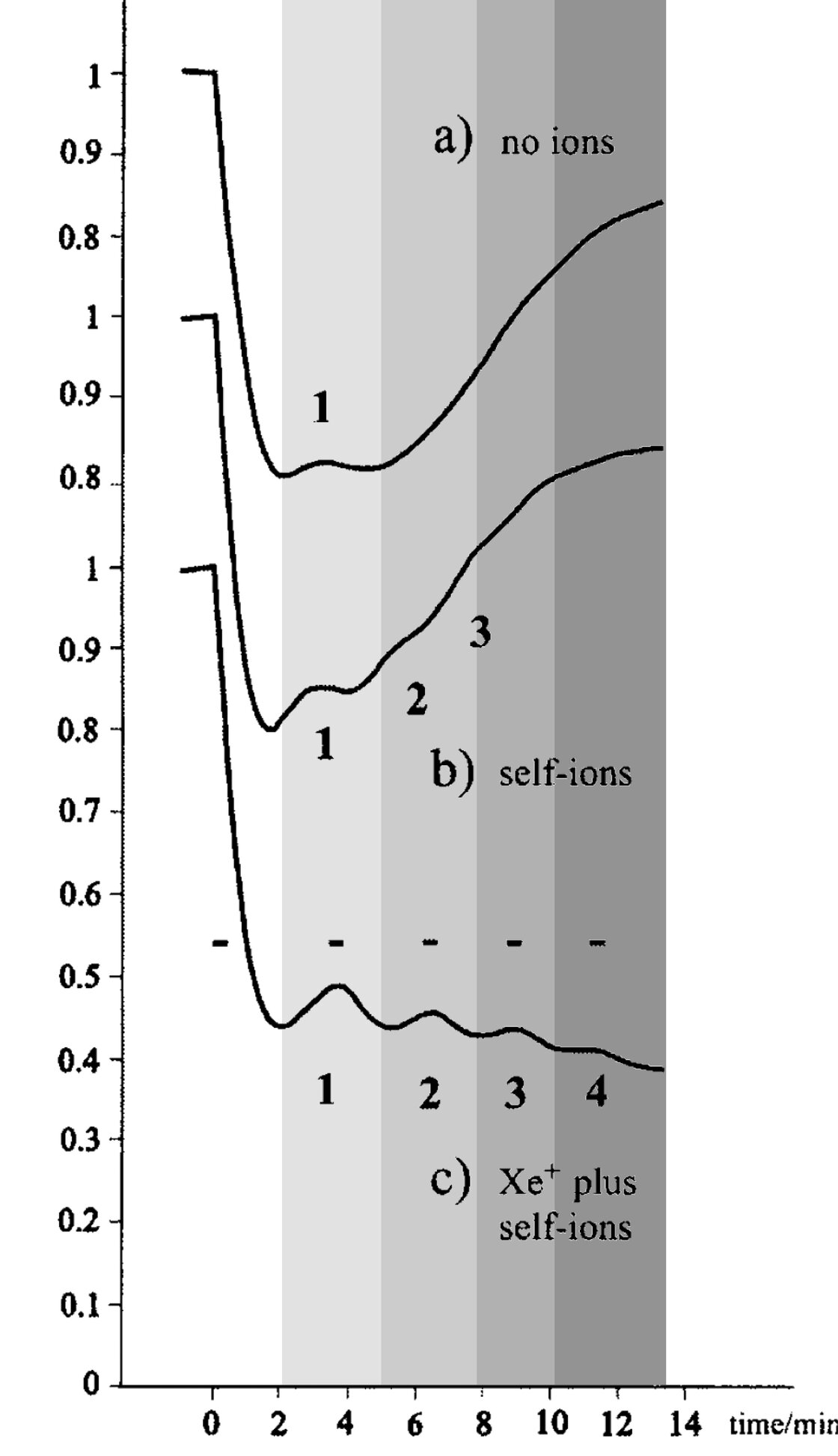

The EFM 3i is specifically designed to facilitate layer-by-layer growth in cases where it does not occur naturally. It allows for the controlled evaporation of the target material and the simultaneous generation of ions to create additional surface defects (Ion-Beam-Assisted Deposition (IBAD)).

Based on the successful design of the EFM 3, the EFM 3i is specifically designed to facilitate layer-by-layer growth in cases where it does not occur naturally. It allows for the controlled evaporation of the target material and the simultaneous generation of ions to create additional surface defects (Ion-Beam- Assisted Deposition (IBAD)). The ions can be produced either by an intrinsic process from the evaporated target material, or from inert gases with the help of an integrated gas inlet. The ions are focused onto the substrate by an electro-static lens. This focusing lens can adjust the ratio of ions to neutrals within the deposition area at the target and hence the additionally induced defect density.

Alternatively sensitive substrate materials can be protected against ion bombardment by a repelling lens voltage (see EFM 3s). The dedicated EVC 300i power supply supports not only the evaporation process but also supplies the additional lens voltage and includes a sample current meter. Due to the special design of the ionization region the max. crucible size is limited compared to the EFM 3.

More Information

Electronics & Software

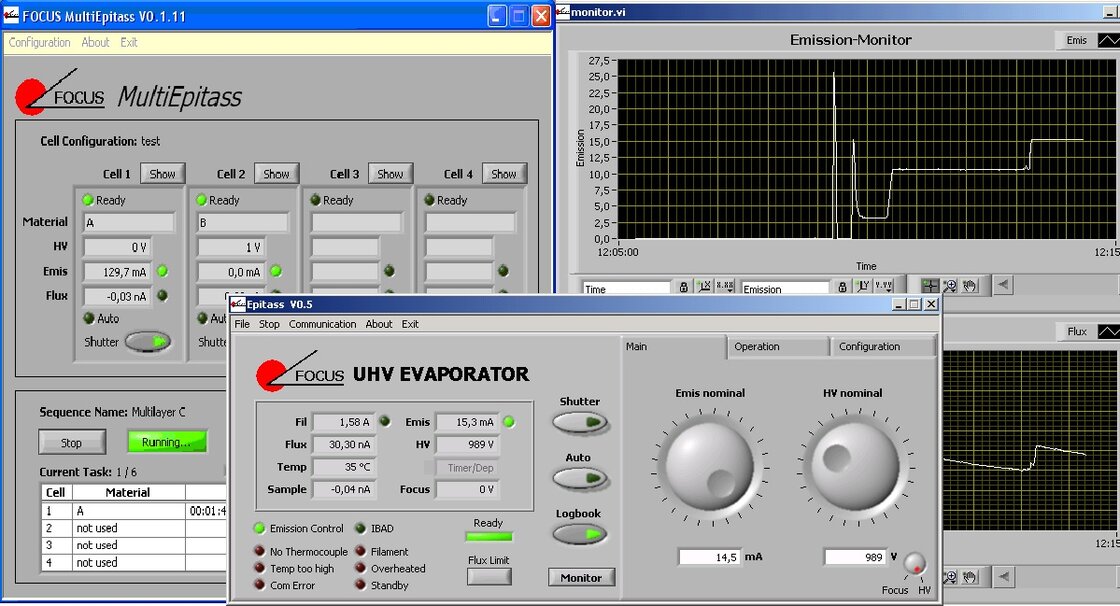

The microprocessor controlled EVC 300i power supplies in combination with the Epitass® software make the operation of all EFM-type UHV evaporators very convenient and safe. With up to 300 W power and up to 1 kV output they are sufficient for the evaporation of any desired material.

The EVC 300i power supply provides a regulated fi lament emission current down to 1 mA in order to precisely regulate crucible temperatures down to 100 °C e.g. for molecules (see front page). Between 100 °C and 800 °C the temperature stability is 0.1 °C or better.

The dedicated EVC 300i power supply supports not only the evaporation process but also supplies the additional lens voltage and includes a sample current meter. Due to the special design of the ionization region the max. crucible size is limited compared to the EFM 3/4.

As a unique feature Epitass® software has a temperature display providing the actual crucible temperature.

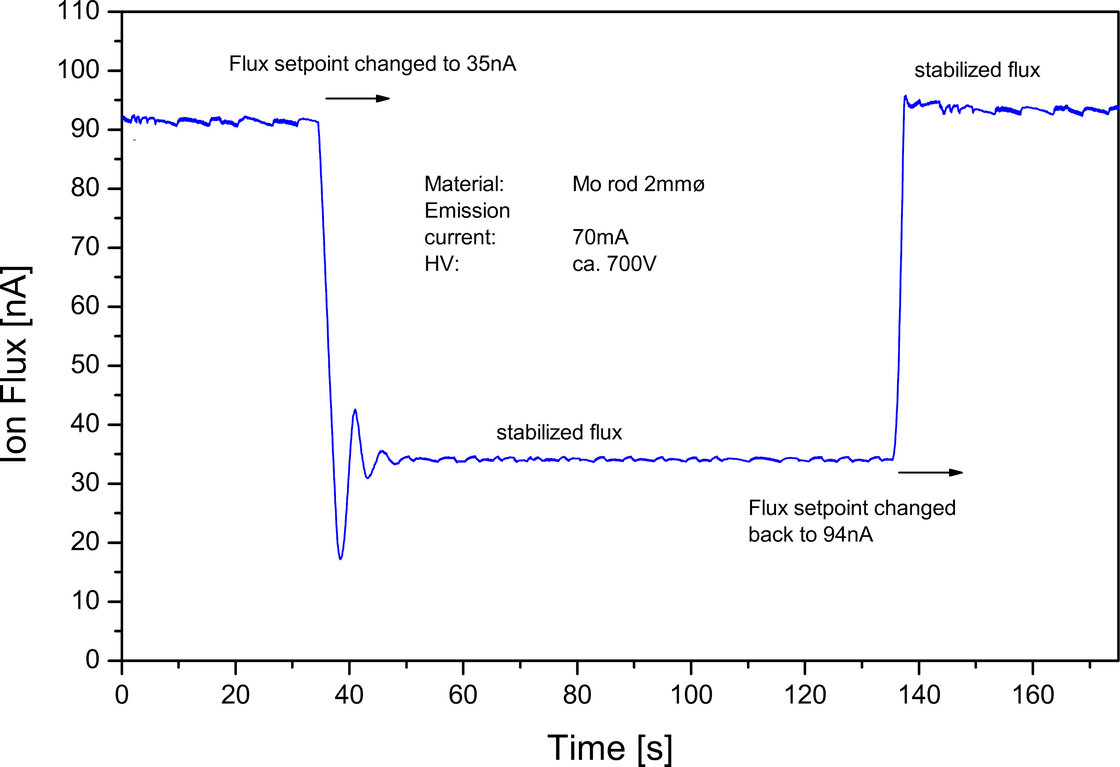

The EVC 300i power supplies come with full flux regulator in addition to the emission current regulator which can be programmed for constant flux or integral flux values.

All parameters of the EVC power supplies including those for the optional motorised shutter can be set manually on the front panel or via the Lab VIEW™-based Epitass® software.

For Multilayer growth or co-evaporation from different cells several EVC power supplies need to be controlled. This functionality is provided by the MultiEpitass® software which can control up to four different cells mastering the individual Epitass® software of each EVC power supply. All evaporators can be equipped with a motorised shutter which is either mounted at the factory or can easily be refitted by the customer.

Evaporants

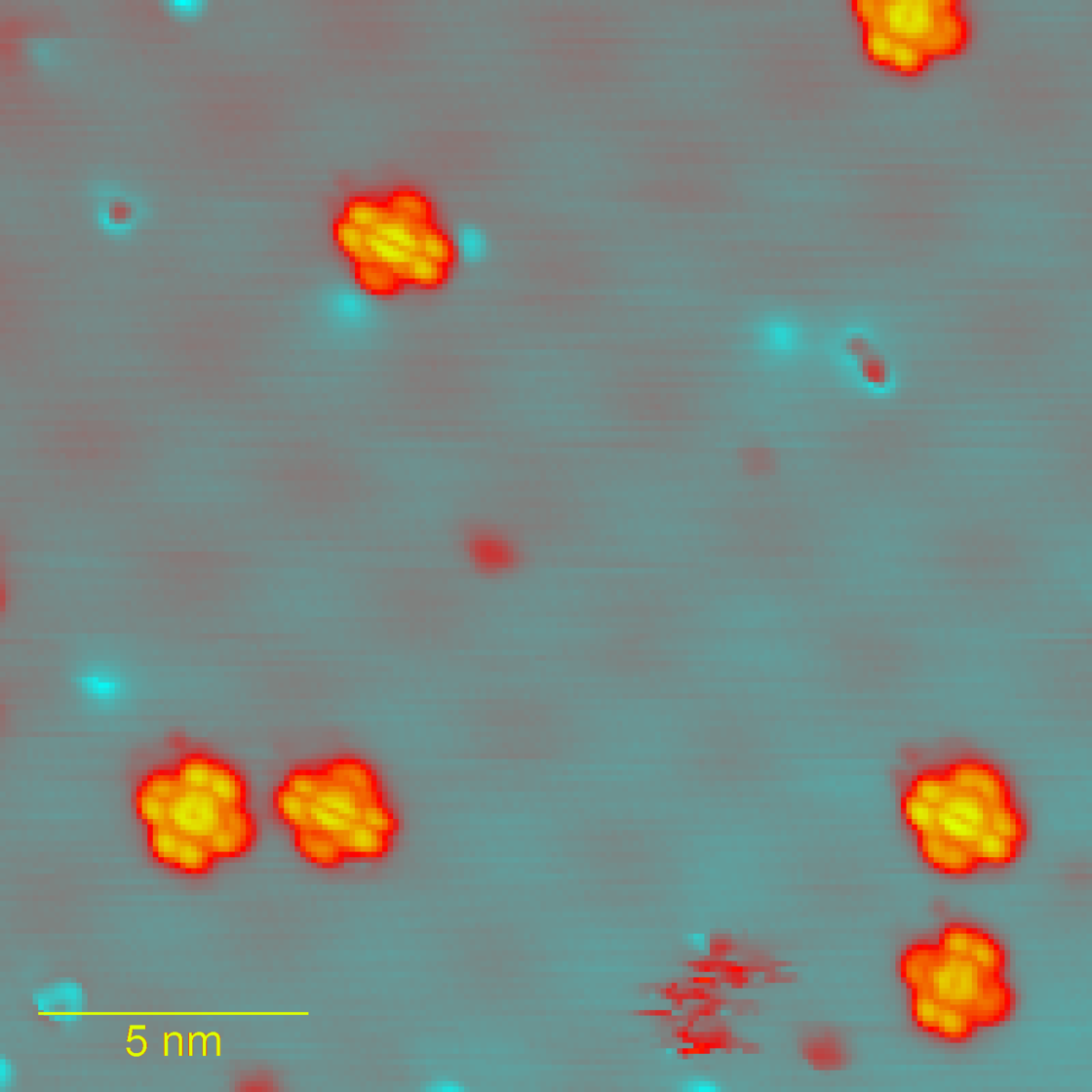

The EFM e-beam evaporators originally have been designed for ultra-pure evaporation of magnetic materials such as Fe, Co, Cr, Mn and Ni as sub-monolayer and multilayer thin films. Materials like Pt, Ag, Au, Al, Ti, Ta, W and semiconductors, e.g. silicon, can be evaporated with the highest purity. Recent innovations allow using the EFM 3 or EFM 3i for a broader range of materials than ever before. In order to handle larger rods an optional 50 mm z-shift is available.

Other materials are:

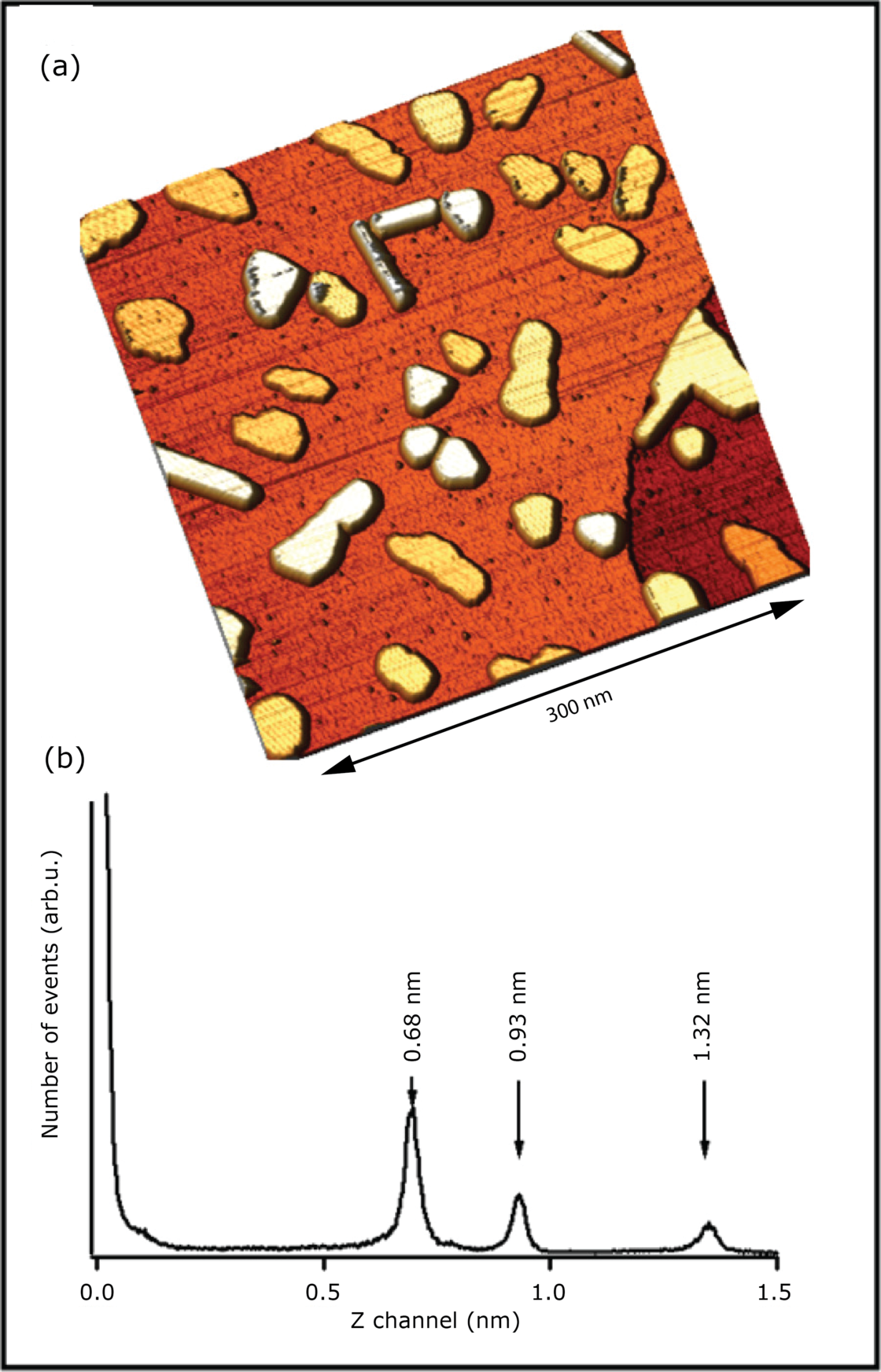

- Organics (down to individual molecules)

- Insulators such as CaF2

Specifications

100 °C - 3300 °C

Rods and crucibles

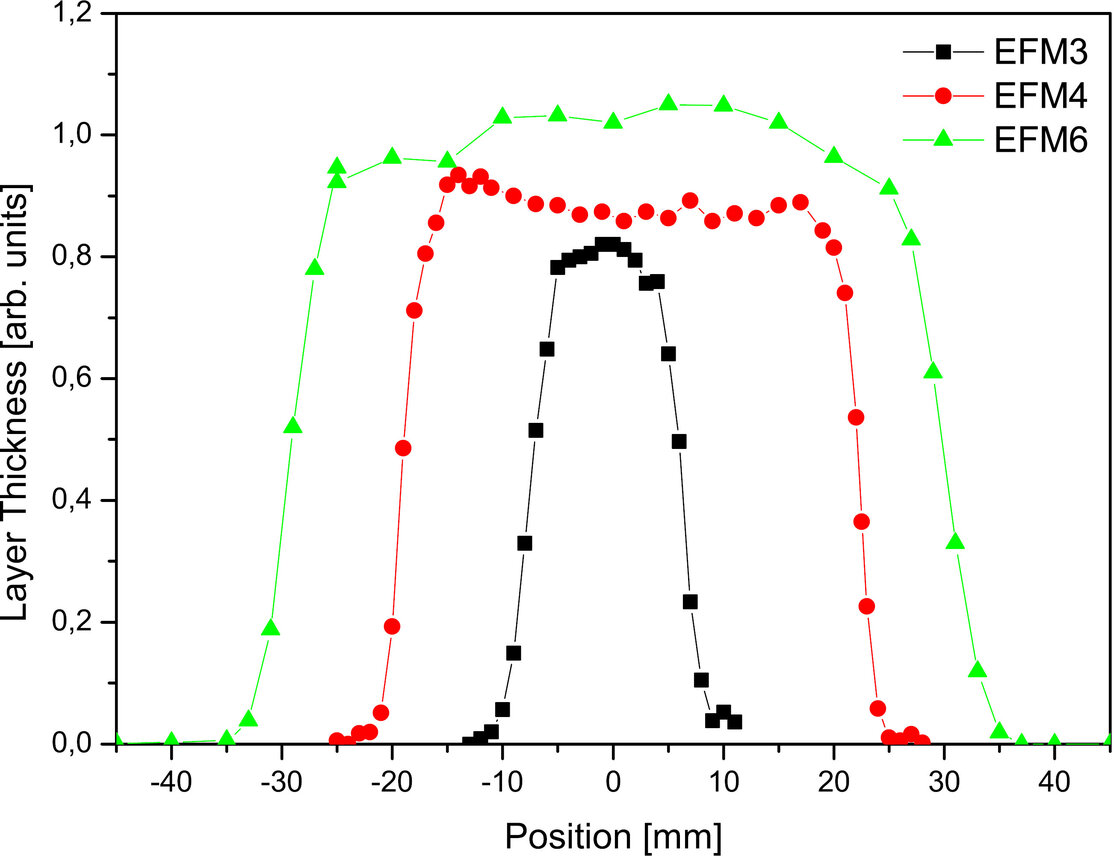

Ø 4 – 20 mm

By z-shift

Integral part of base package

Up to 250 °C

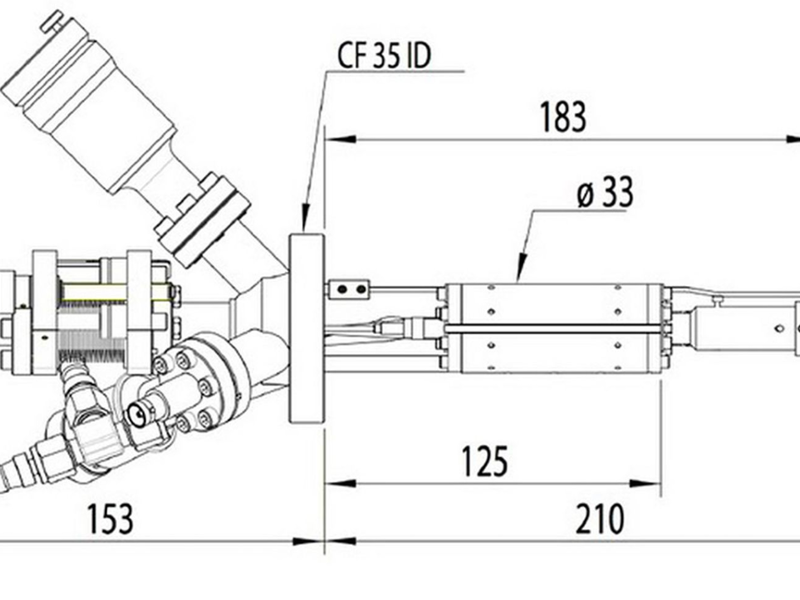

DN 40 CF

210 mm

Ion focusing lens and ion suppression

Co-deposition package with shutter motor and multi-pocket control

Special length

Valve for gas in-let

For full specifications and more information about product options, please do not hesitate to contact your local sales representative. Find the contact details here: Contact Us