LEED 600 MCP

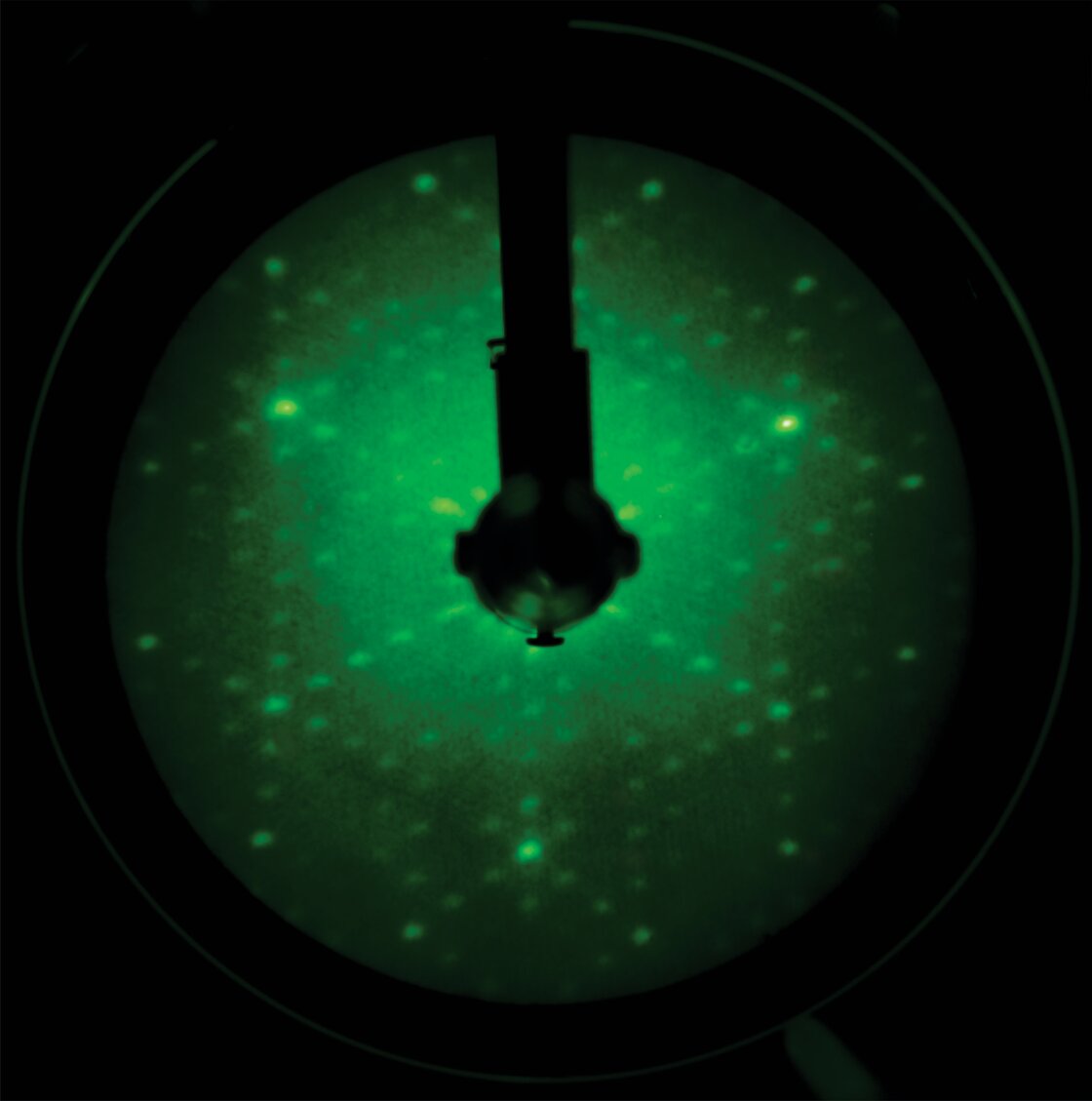

Compact LEED for Organic Films & Molecular Beam Epitaxy

- High Image Sensitivity at the Primary Beam Current – 50 pA

- Single/Dual 75 mm Microchannel Plates

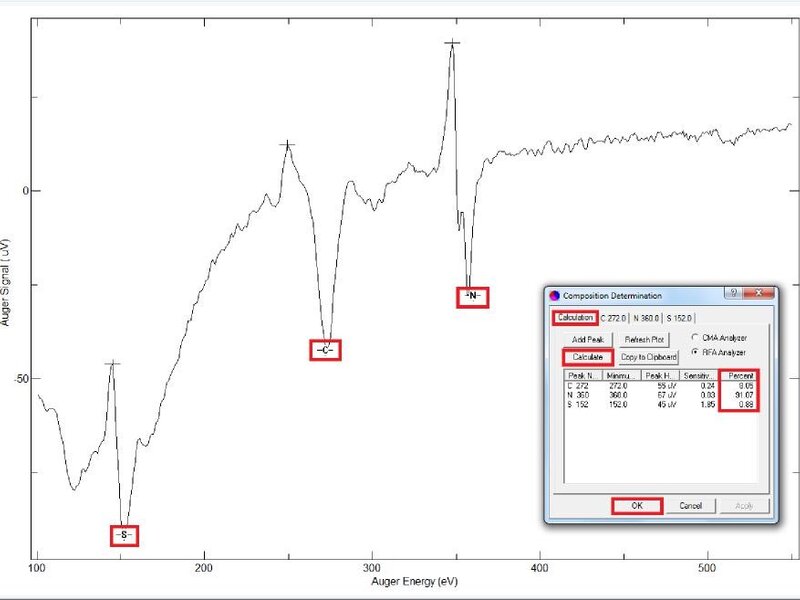

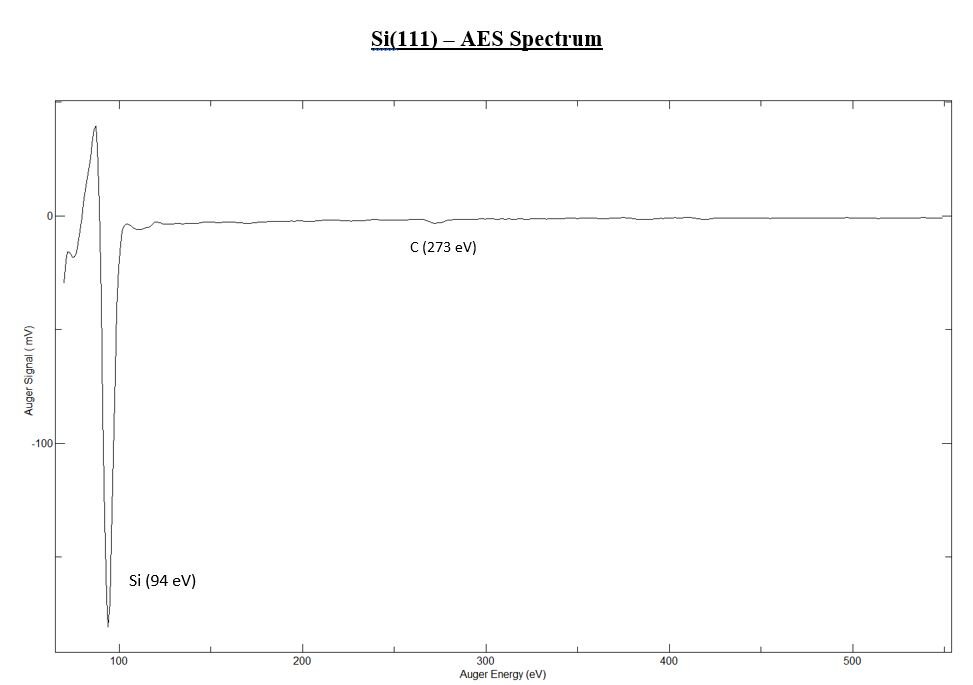

- AES at Beam Current 50 µA – 10 µA

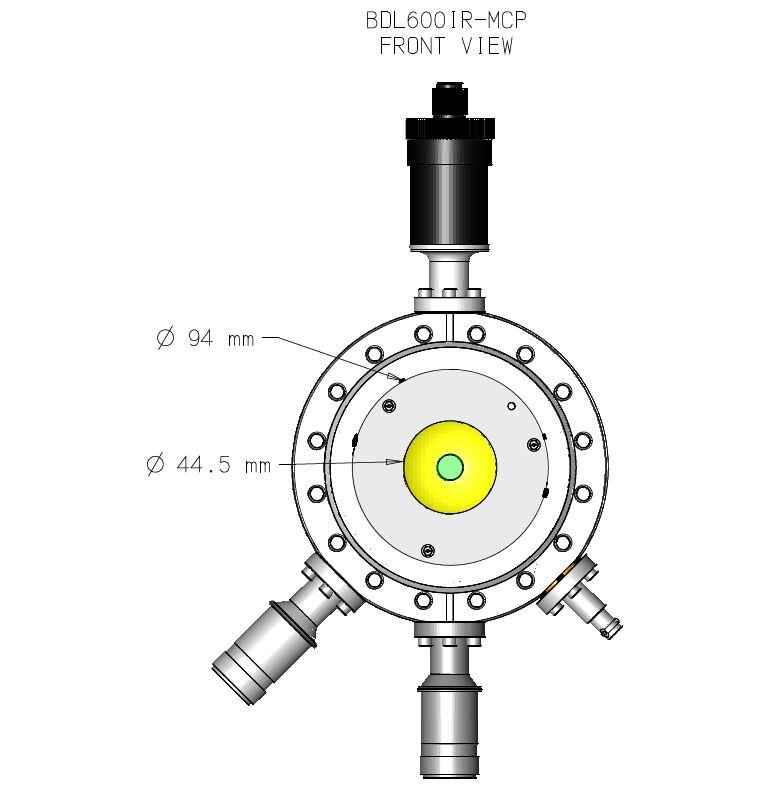

- Large Angle (92°) Fluorescent LEED Display and superior magnetic shielding

- Miniature electron gun with large coherence width double focusing

- Suitable for ESDIAD

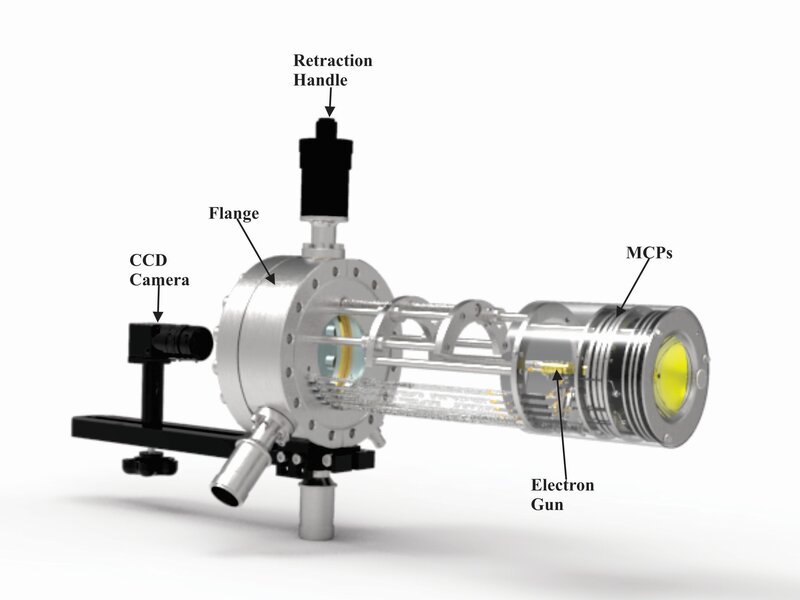

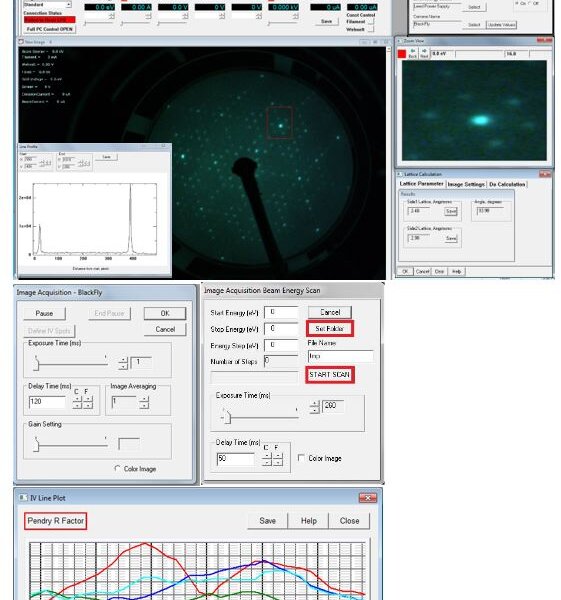

- Convenient LEED Image Capture with External CCD Camera

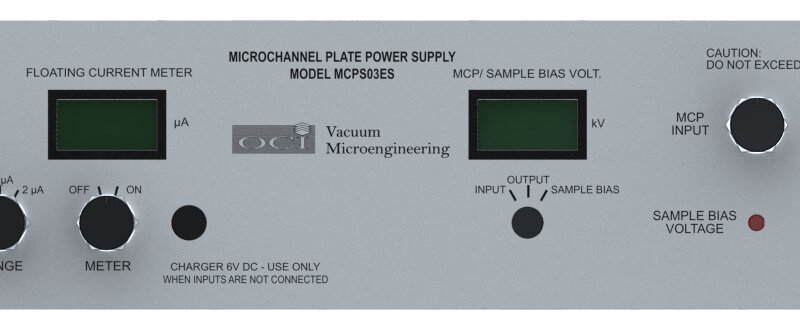

- Simple and Powerful Operation with Digital Controller

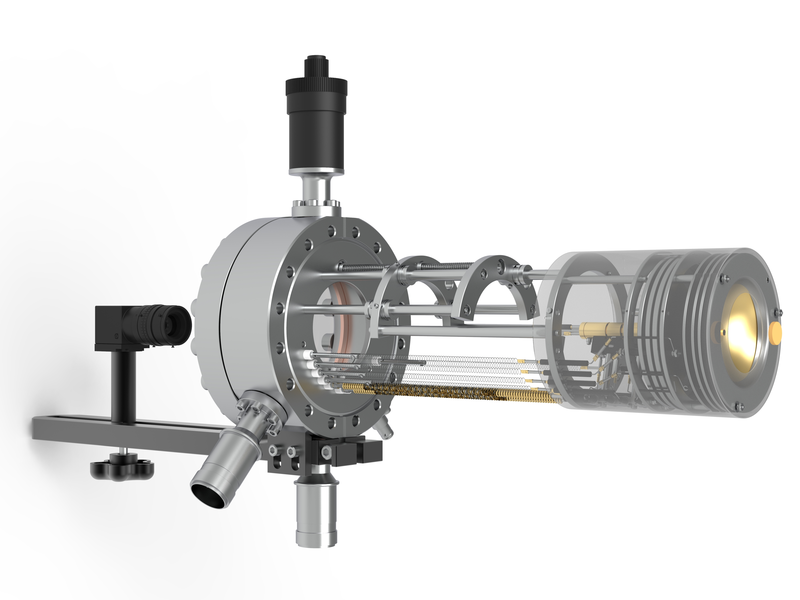

The LEED 600 MCP has LEED and AES capabilities using a miniature electron gun, set of concentric grids and a conductive, phosphor coated screen. In addition, this optic model incorporates the high gain of microchannel plates.

It is an extremely reliable high-performance LEED instrument which operates with up to date digital power supply. The retraction mechanism has outstanding mechanical properties ensuring smooth day-to-day operation as experienced by our large user base over decades. The wide viewing angle (92° at 51 mm sample distance) and minimal shadowing of the screen by the miniature electron gun give a maximum visible LEED pattern.

More Information

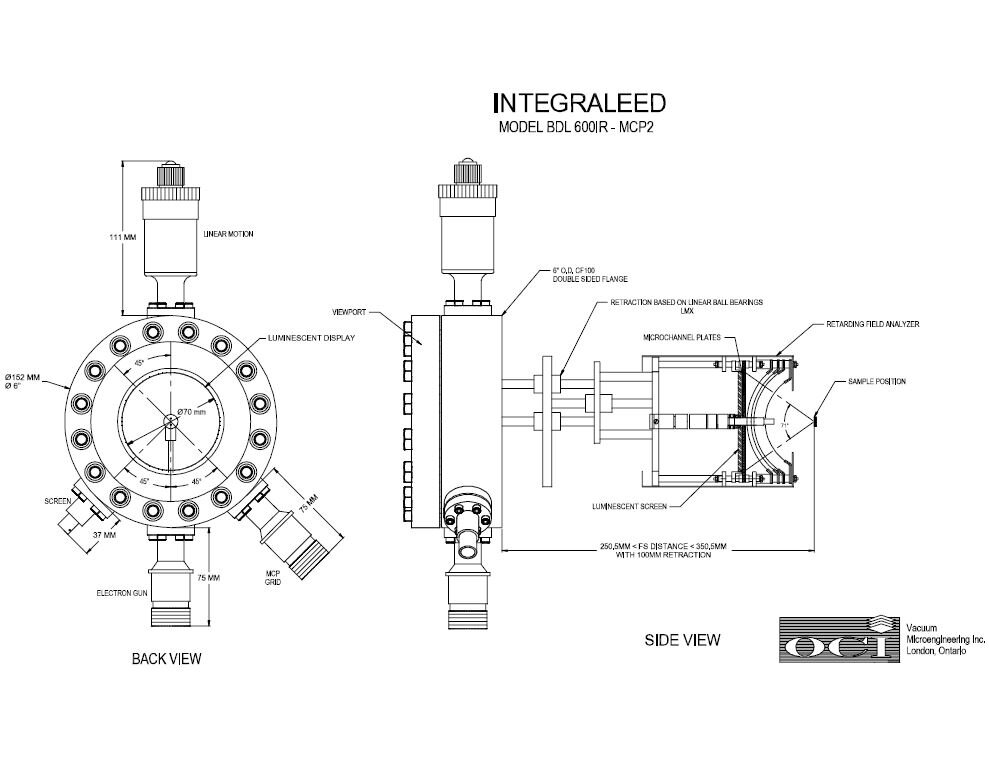

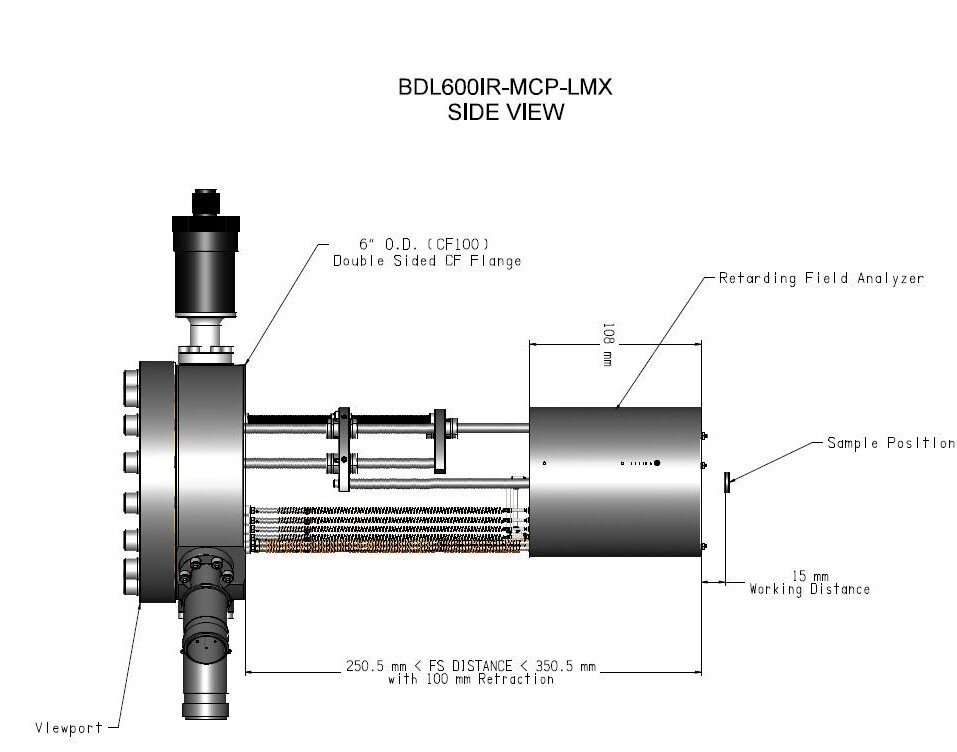

LMX length calculation for LEED 600 MCP (model BDL600IR-MCP):

FS = 135.5 mm + 2LMX – OV + WD; where FS is the flange to sample distance, LMX is the retraction distance, OV is the overlapping distance, WD is the working distance and the 135.5 mm value is a constant related to this optic model.

If the calculated FS value is longer than the actual port length a nipple adapter can be added as a spacer between the LEED optics and the UHV chamber. The nipple length can be calculated as follows:

NL = FS – PL; where NL is nipple length and PL is port length.

Configuration Guide and Specifications

The LEED 600 MCP optics is controlled using either a LPS075-D or LPS300-D power supply. The LPS075-D is used to operate the optic in LEED mode only whereas the LPS300-D in conjunction with the LOA10-AES lock-in controller and AUS30 input coupler is used to operate the optics in LEED and AES modes. Integral shutter (model ISH-6) and LaB6 filament (model LaB6) are further options.

Please contact us for the detailed Configuration and Specification Guide.

Specifications

Fused silica coated with indium-tin oxide conductive layer and P31 phosphor (ZnS:Ag:Cu-green, 525 nm wavelength)

92° angle of acceptance from sample at a distance of 51 mm

Concentric assembly of hemispherical grids

15 mm from sample

Gold coated tungsten wire mesh (100 mesh, 81 % transparency)

0.2 % - 0.5 % at low modulation voltages

6" standard viewport

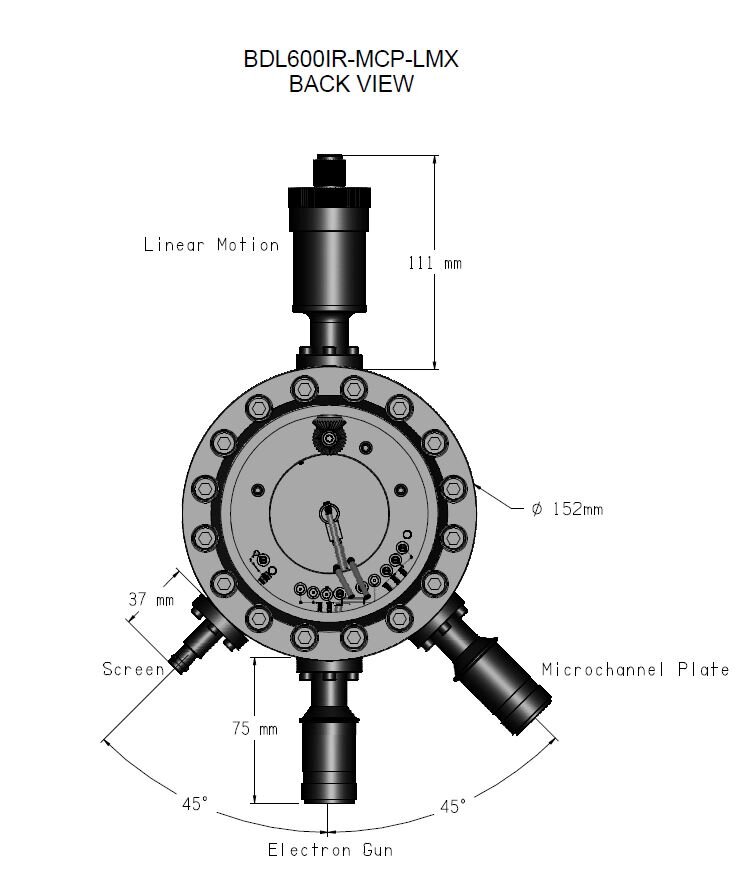

Up to 100 mm retraction from sample; linear ball bearing and acme thread with all spring electr. connections

Mu-metal cylinder with front cover for maximum attenuation

Extreme-high-vacuum compatibility with stainless steel, high alumina and Au-plated copper alloy materials

6"(CF100) double sided conflat flange with sample distance 145 mm – 400 mm

Under vacuum, 250 °C maximum

–

LEED – 2 µA at 100 eV and 0.5 mm beam size, AES - up to 100 µA at 3 keV

From 1 mm to 250 µm - adjusted by Wehnelt potential, limited by exchangeable aperture down to 50 µm

Tungsten-2 % thoriated filament standard,

single crystal LaB6 filament optional

0.45 eV (thoriated - tungsten filament)

10 mm lens diameter and 80 mm length

For full specifications and more information about product options, please do not hesitate to contact your local sales representative. Find the contact details here: Contact Us