DFS30

Stay Focused, Save Time

- Electronically shift the analyser focal point to the emission spot

- Increase effective sample lifetime through fast and precise alignment

- Electrostatic 3D Focus Adjustment in X, Y, Z (WD) for best results

- Deflection mode full cone measurements without matrix element effects

- Upgrade from DA30-L available

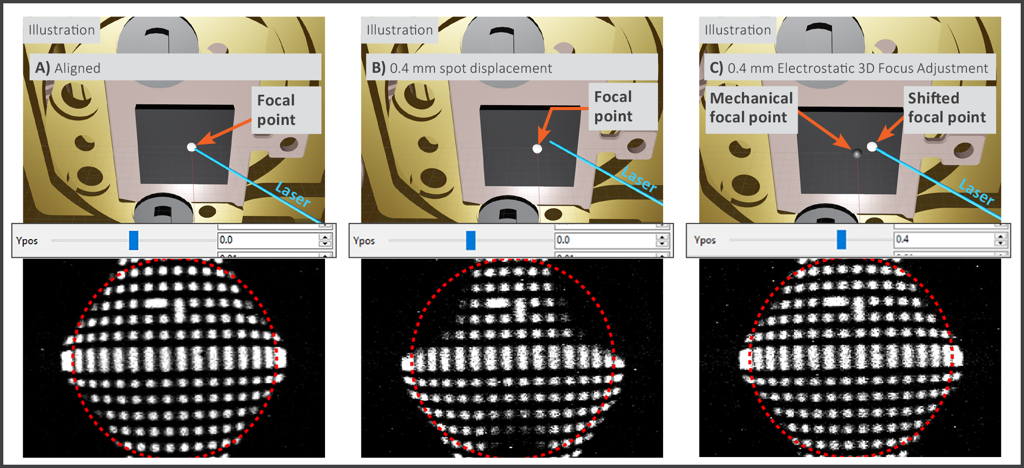

The DFS30 analyser features ground-breaking Electrostatic 3D Focus Adjustment technology - a major advancement in replacing imprecise mechanical movements with electronic precision and repeatability. This provides significantly improved workflow, speed, and reproducibility when optimizing experimental conditions. High quality ARPES measurements, particularly micro/nanoARPES, require optimised alignment of the photon spot, sample, and analyser focal point. The DFS30 simplifies this alignment with electronic adjustment of the analyser focal point in X, Y and Z (working distance) to the photoelectron emission spot.

The focus on µARPES & nanoARPES in conjunction with high resolution measurements has highlighted the challenge of obtaining optimal alignment. Without optimal alignment deflection mode measurement performance is reduced. Electrostatic 3D Focus Adjustment enables shifting the analyser’s focus in 3D to the photoelectron emission spot, leaving the sample and photon spot mechanically static. This saves hours of alignment and increases the effective sample lifetime.

The electronic shifting of the analyser focal point requires dynamic lens tables for deflection, angular and transmission modes. These lens tables are now calculated in real time based on a set of calibrated and adjustable sliders.

Pushing Boundaries & Innovation

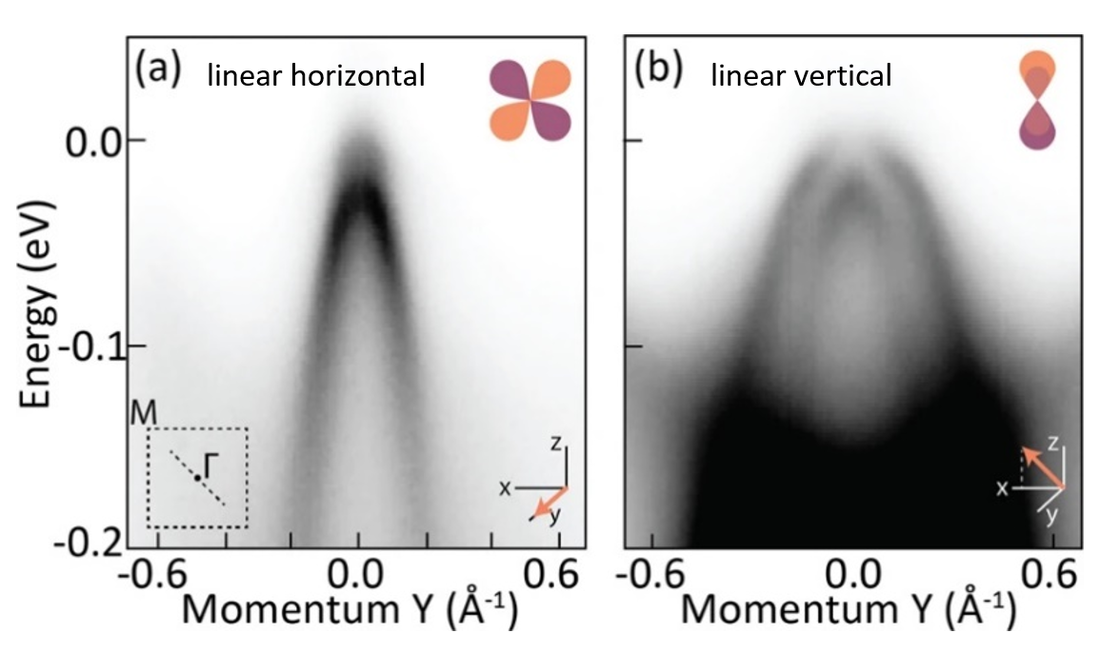

Deflection mode measurements, introduced by Scienta Omicron in 2013, improved ARPES measurements by replacing imprecise mechanical motion of the sample needed to probe the angular distribution with electrostatic deflection. This enables the experimental geometry to stay mechanically static while still accessing the off-axis electron distribution to measure without introducing matrix element effects.

Science constantly pushes boundaries and as new demands arise; experimental equipment must improve. At certain points, refining the existing parameters is no longer sufficient. Instead, a paradigm shift based on true innovation and deep understanding of limiting factors is required to substantially improve the experimental technique.

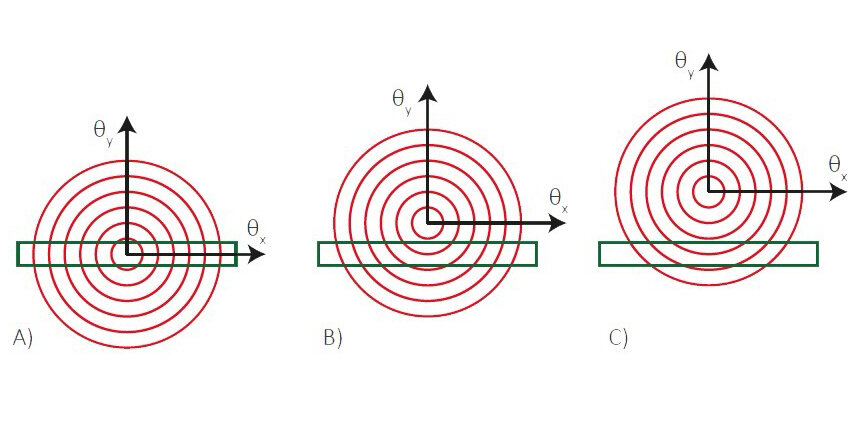

This applies particularly to high resolution ARPES experiments where deflection mode analysers have become the established standard. For θy deflections larger than a few degrees, control of the emission spot position has proven far more critical than for earlier generation instrumentation. To reach the next substantial experimental improvement, electrostatic 3D focal adjustment has been developed (patent pending) and is implemented in the DFS30 analyser.

More Information

Electrostatic 3D Focus Adjustment

With Electrostatic 3D Focus Adjustment technology, the analyser’s focal point can shift in X, Y and Z (working distance) to align with the photoelectron emission spot. Dynamic lens tables based on a parametric model of the sample region are generated in real time for deflection, angular and transmission modes. This significantly improves the workflow, speed, and reproducibility when optimizing experimental conditions and ensuring best measurement performance. By this, imprecise mechanical movements of sample and photon source are replaced with electronic precision and repeatability leading to significant time saving and data quality increase.

Deflection Advantage

The deflection feature is a big advantage as it allows to keep the sample in a fixed position and instead uses the deflectors to change the angular range in θy projected on to the analyser slit. This ensures the same position of the sample is probed during the whole measurement. In addition, keeping the experimental geometry fixed throughout the measurement sequence avoids matrix element effects which are caused by variations in ionisation cross section for different photon to sample angles. This allows to acquire higher quality data using the faster and more precise electronic deflection compared with mechanical sample movement. Another advantage, for some samples, is that decreased rotation requirements allow manipulators with fewer degrees of freedom to be used. This ultimately allows for lower sample temperatures to be reached.

Highest Performance at the Lowest Kinetic Energies

The DFS30-8000 is not a serial production analyser but tailored to the particular experiment of each customer. With angular and deflection modes from 0.5 eV and an adapted electronics rack with boards for ultra-low noise, this is the model of choice for e.g., ultra-high resolution laser-ARPES measurements. Achieving good performance at low kinetic energies puts high demands on the analyser mechanics. This is especially true for the 8000 models which feature lower pass energies and smaller entrance slit sizes in support of ultra-high resolution at low kinetic energies.

To ensure best possible performance of the analyser a number of important processes have been optimised:

- The high voltage electronics design has been optimised for high energy resolution using ultra stable HV-supplies. Each HV-supply is checked individually for low noise and long-term stability. Special attention is paid to common grounding of all analyser parts to the HV-electronics.

- Critical dimensions of analyser parts are trimmed manually to reach the design criteria. Special care is taken to the mu-metal connections inside the analyser and the analyser is demagnetised at customer site.

- The analyser is supplied with a customised slit set and lens table for 0.5 eV pass energy enabling ultra-high resolution measurements.

DFS30-8000 UPS Upgrade

Specifications

Multi-channel (snapshot acquisition)

Particle counting

From <1.0 meV FWHM

0.5 eV – 1 500 eV

± 3.5°, ± 7°, ± 15°

From 0.5 eV – 1 500 eV

From 0.5 eV – 200 eV

Yes

< 10-5 mbar

DN200CF (10” O.D.)

Yes

± 1 mm

34 mm (variable ± 2.5mm)

For full specifications and more information about product options, please do not hesitate to contact your local sales representative. Find the contact details here: Contact Us

Downloads

DFS30: Stay Focused, Save Time

The DFS30 analyser features ground-breaking Electrostatic 3D Focus Adjustment technology - a major advancement in replacing imprecise mechanical movements with electronic precision and repeatability. This provides significantly improved workflow, speed, and reproducibility when optimizing experimental conditions. High quality ARPES measurements, particularly μARPES and nanoARPES, require optimised alignment of the photon source, sample, and analyser focal point. The DFS30 simplifies this with electronic adjustment of the analyser focal point.

DSF30: Release Note

The DFS30 analyser features ground-breaking Electrostatic 3D Focus Adjustment technology - a major advancement in replacing imprecise mechanical movements with electronic precision and repeatability. This provides significantly improved workflow, speed, and reproducibility when optimising experimental conditions. High quality ARPES measurements, particularly μARPES and nanoARPES, require optimised alignment of the photon spot, sample, and analyser focal point. The DFS30 simplifies this alignment with electronic adjustment of the analyser focal point.